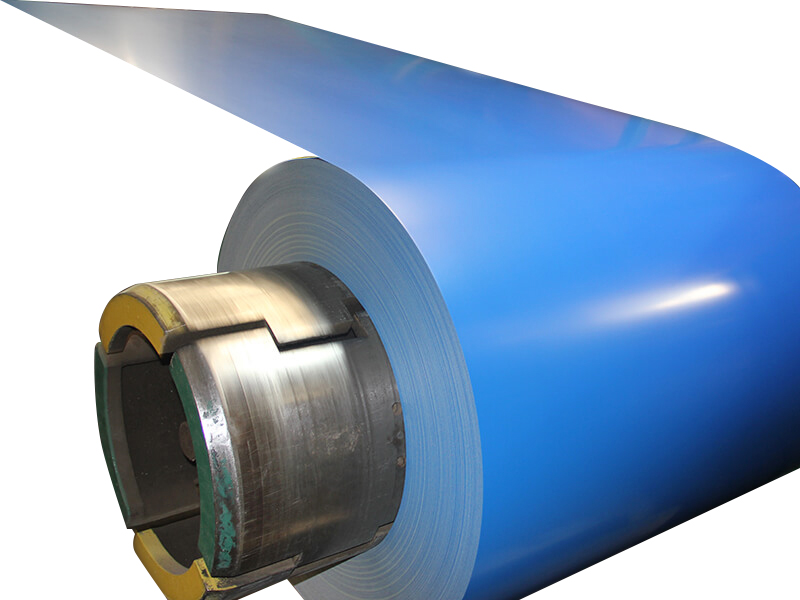

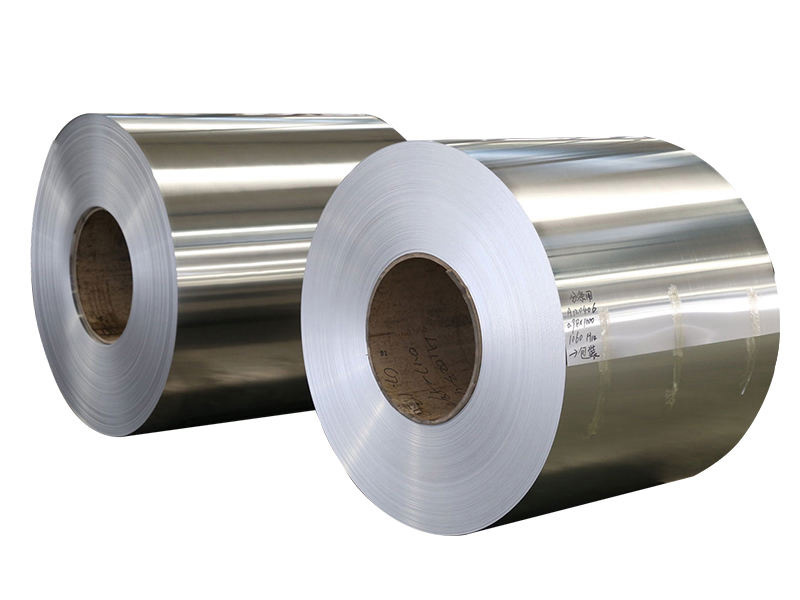

24 Gauge Metal Coil

We produce PVDF, SMP 24 gauge metal coil, using beckers, PPG brand paint, top coat 15-30 microns, back primer 5-20 microns, meeting the needs of

We produce PVDF, SMP 24 gauge metal coil, using beckers, PPG brand paint, top coat 15-30 microns, back primer 5-20 microns, meeting the needs of

We produce and sell 29 gauge metal coils, including galvanized steel, galvalume steel, prepainted steel, aluminum coils. 29 gauge aluminum = 0.0113 Inches 29 gauge

Application Construction: Roofing, cladding, profiling, tiles, ceiling, Pre-engineered Buildings. General industry: Pipes, enclosures for electrical equipment, HVAC system. Appliances: Washing machines, tumble dryers, refrigerators. Aluzinc

Production Process The main production processes of the prepainted galvalume production line include pre-treatment process, coating process, and baking process. Uncoiling – sewing – degreasing

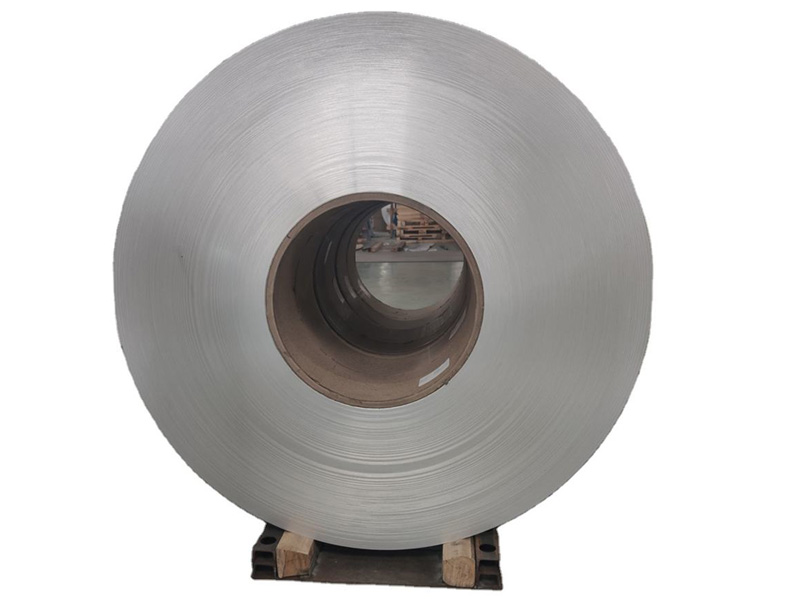

Dx51d z200 refers to galvanized steel coil that undergoes a continuous hot-dip galvanizing process. This method offers the steel coil broad protection from corrosion by

Dx51d z140 refers to steel products with high formability for cold forming, as indicated in the first letter D. The letter X indicates no specific

Dx51d AZ150 is a hot-dip aluminum-zinc steel alloy with a coating of 55 percent aluminum, 1.6 percent silicon, and 43.4 percent zinc. The chemical composition

AZ150 Galvalume is a hot-dip aluminium-zinc alloy coating steel. The resulting coating has excellent corrosion resistance and can be used in harsh environments. This combination

AZ55 galvalume is an aluminum alloy formulated to provide superior corrosion resistance, strength, and elasticity. The alloy comprises two parts: zirconium, which offers corrosion resistance,

AZ50 galvalume steel is a zinc alloy type with a zinc base. It is an alloy with up to 50% aluminum, giving it its characteristic

Organic-coated steel is created by applying an organic coating material on rolled metal strips through the continuous coil coating process. The application process involves cleaning

Zincalume steel coil with Activate Technology is a steel made by adding zinc, aluminum, or magnesium to the primary steel alloy, making it a robust

3105 aluminum coil is a type of rolled aluminum that has been manufactured with a thickness of 0.3 inches. This product can be used for

6061 Aluminum Coil is a popular choice of manufacturers for general-purpose and construction applications. Its primary alloying elements include 1% magnesium and 0.6% silicon. High

1100 Aluminum Coil is a widely-used industrial soft, low-strength metal for making chemical equipment, heat exchangers, and decorative trim applications. This commercially pure alloy has

1060 aluminum is a very popular alloy in the aerospace, automotive, and construction industries. This alloy is known for its formability and corrosion resistance, making

3003 Aluminum Coil is an aluminum alloy with a high percentage of silicon and iron, making it easy to form and weld. It can be

5052 Aluminum Coil is an alloy grade under the Standard Specification for Aluminum and Aluminum – Alloy Sheet and Plate 1 on B 209 –

Dx51d Z150 galvanized steel coil is a coating and steel grade designation under the ASTM A653 / A653M requirements or specifications. The direct function of

Different types of hot-dipped galvanized steel coils are produced, one of which is DX51D Z100. Learn more about it here. What is a DX51D Z100

Learn about the Z275 galvanized steel coil in this simple but comprehensive overview. What is a Z275 galvanized steel coil? Galvanized steel coil Z275 is

All steel products for commercial, agricultural, mechanical, and industrial use are subject to ASTM standard specifications. Zinc-coated (galvanized) steel coil by the Hot-Dip Process like

A Z40 galvanized steel coil is helpful in different applications, including manufacturing and fabrication environments. It is also durable, sustainable, and cost-effective. There are different

What is zinc aluminum-magnesium coated steel? The Zinc Aluminum-Magnesium coated steel is a new product in the global steel trading industry. It is a result

Mechanism of corrosion resistance Corrosion or rust may be avoided by creating a barrier on the surface of steel iron. This method is also known

G90 galvanized steel sheet is a coating thickness designation specified under ASTM A653 galvanizing specification. It indicates a zinc coating of 0.90 ounces per square

ASTM A653, or the standard specification for steel sheet, zinc-coated (galvanized) or zinc-iron alloy coated (galvannealed) by the Hot-Dip Process, shows products that conform to

Production Process of Galvanized Steel Strip In the production process of galvanized steel strip, it has gone through very rigorous procedures and multiple production processes.

G40 galvanized steel coil is a common zinc coating weight or designation that is directly proportional to the expected life service of the steel product.

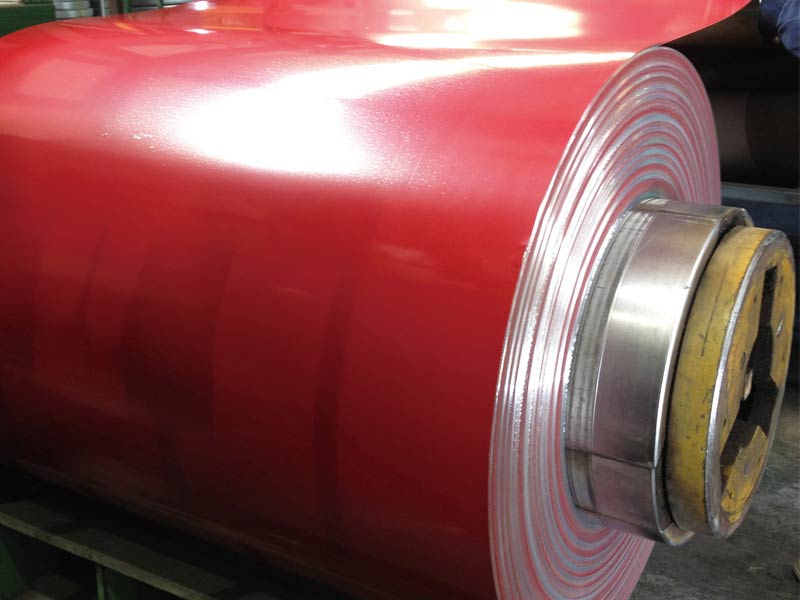

The pre-painted steel sheet is based on cold-rolled steel sheet and galvanized steel sheet, after surface pretreatment (degreasing, cleaning, chemical conversion treatment), and coating (roller

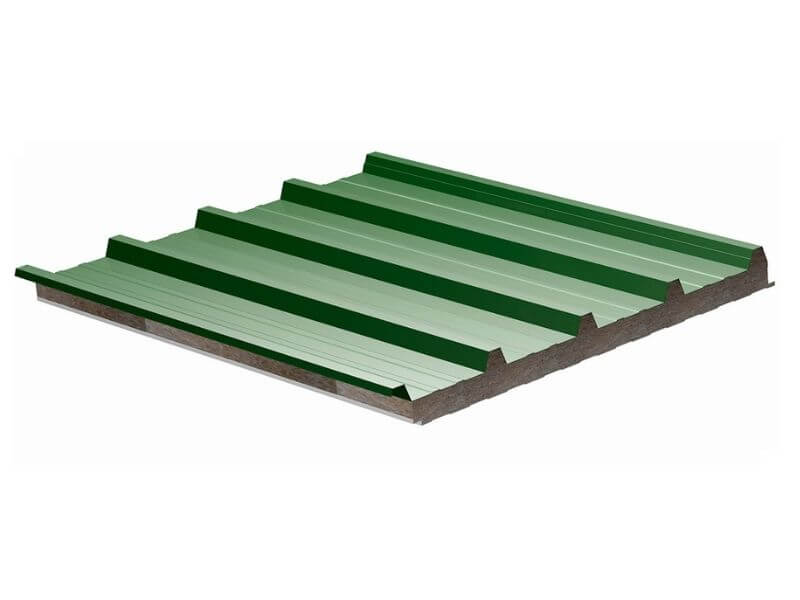

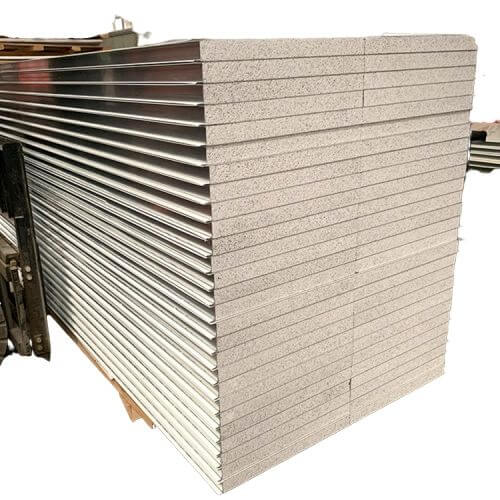

What is the use of Colour-coated steel? Construction Color-coated steel coils are mainly used in construction projects. After being processed into corrugated boards or sandwich

Surface Structure Spangled galvanized steel sheet is the spangle obtained by the condensation of the zinc coating under normal conditions after galvanizing. It is mainly

PPGL Coil uses DX51D+AZ, and q195 and galvalume steel sheet as the substrate, PE coating is our most commonly produced, it can be used for up to 10 years.

Uses of Prepainted Galvanized Steel Coils The main uses of pre-painted galvanized steel coils are home appliances and construction. Home appliance uses are mainly side

Material: CGCC, DX51D,Q195,Q235

Grade: SGCC,DX51D+AZ

Alu-Zinc Coating: 20-120g/m2

Thickness :0.13-0.7 mm

Width: 600-1250 mm

Coil ID: 508/610mm

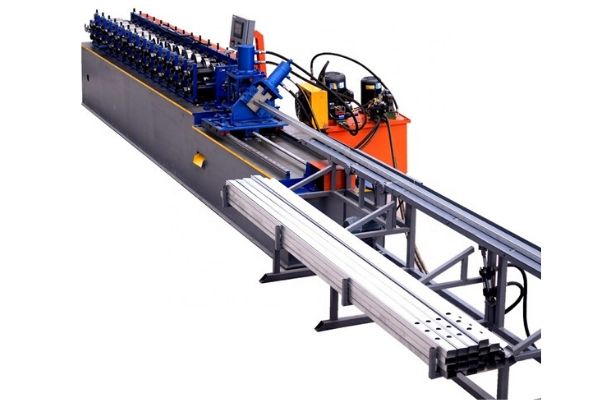

Introduction: The metal stud roll forming machine applies strip steel as the raw material and undergoes continuous roll forming. It is fast in production, environmentally

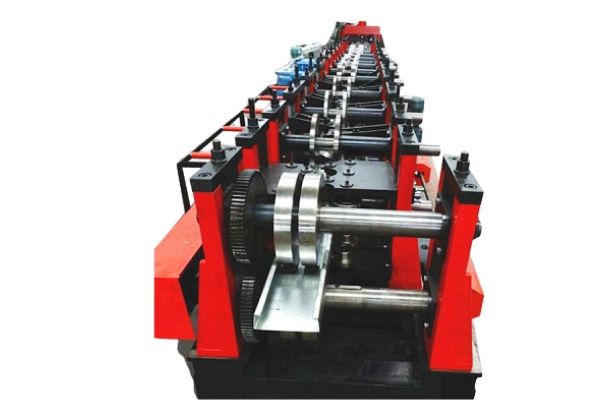

The working principle of the steel pipe roll forming machine: The strip steel is introduced into the pipe welding machine through the feeding machine, and

The Specification of Cold Roll Forming Machine:

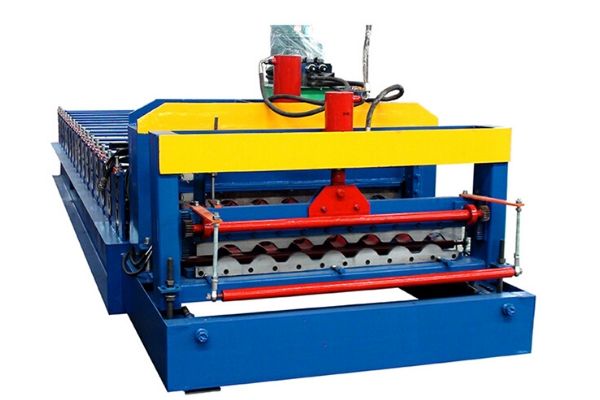

The Structure of Glazed Tile Roll Forming Machine: The glazed tile roll forming machine is mainly composed of left and right bodies, bottom connection bar, upper

The Introduction of the Cable Tray Roll Forming Machine: Cable tray roll forming machine is a kind of equipment that integrates many technologies including

Introduction: C channel roll forming machine is a single-coil forming unit that can produce various specifications of C-shaped products with a set of steel rolls. The C channel roll forming

The Introduction of the Gutter Roll Forming Machine: The gutter roll forming machine equipment is mainly composed of an active belt shaft, a leveling device,

Introduction: The products produced by the highway guardrail roll forming machine have the characteristics of lightweight, high strength, large bearing capacity, and good seismic resistance,

Introduction: The floor deck produced by the floor deck roll forming machine is formed by galvanized steel sheet through roll bending, and its cross-section is

The Specification of Guide Rail Roll Forming Machine:

Definition: Double-layer roll forming machine is a production machine composed of unwinding, forming, post-forming cutting. Its color plate is flat and beautiful in appearance, uniform

C Purlin Roll Forming Machine: C purlin roll forming machine is a set of a single-roll forming unit whose roll can produce various specifications of

Color-coated aluminum coils are color-coated on aluminum coil. Common fluorocarbon color-coated aluminum and polyester color-coated aluminum are widely used in aluminum-plastic panels, aluminum veneers, and

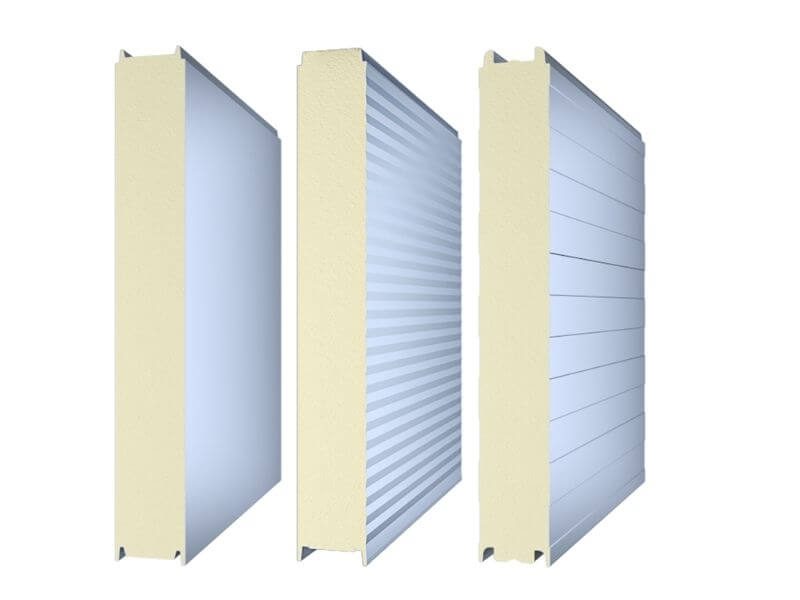

Glass Wool Sandwich Panel The Definition of Glass Wool Sandwich Panel: The glass wool sandwich panel is composed of two layers of upper and lower

What is Galvanized iron sheet? Galvanized iron sheet is a material consisting of a zinc layer applied to sheets of metal that go through a

EPS Sandwich Panel The Definition of the EPS Sandwich Panel: The inner and outer sides of the EPS sandwich panel are glass steel plates, and

Definition: The inner and outer sides of the PU sandwich panel are glass steel plates, and the rigid polyurethane foam of the sandwich layer is

Rock Wool Sandwich Panel RockWool Sandwich Panel Specification Advantages of Rock Wool Sandwich Panel: Excellent fire-resistance performance: The raw materials, production process, and formula used

Advantages of hot–rolled steel coil : 1) Hot rolling can significantly reduce energy consumption and reduce costs. During hot rolling, the metal has high plasticity and

Cold-rolled steel coils have good properties, and cold-rolled strips and steel sheets with thinner thickness and higher precision can be obtained by cold-rolling. High flatness,

Copyright COJIASTEEL | All Rights Reserved