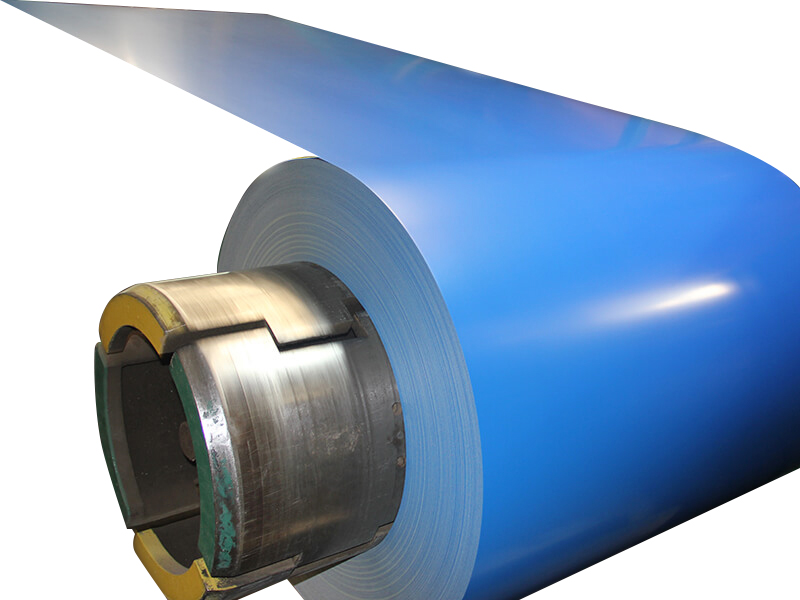

AZ150 Galvalume is a hot-dip aluminium-zinc alloy coating steel. The resulting coating has excellent corrosion resistance and can be used in harsh environments. This combination results in a durable and corrosion-resistant material that can be used in any application with high strength or hardness.

AZ150 galvalume is a high-quality, corrosion-resistant alloy commonly used in the construction and transportation industries. It’s highly resistant to rust, oxidation, and corrosion, making it an excellent choice for those who need to ship items or have them exposed to weather conditions.

What does AZ150 mean?

AZ150 means that in the triple spot test in the en 10346 standard, the minimum total coating mass on both surfaces of the aluminum-zinc alloy coating is 150g per square meter. Equivalent to Total Both Sides in ASTM a792 standard is 0.50 oz/square foot.

AZ150 coating thickness

AZ150 coating single surface coating thickness is 18 microns, double surface coating thickness is 36 microns.

This steel’s coating alloy is made up of 55% aluminium, 43.4% zinc, and 1.6% silica. The coating of this steel serves as general corrosion’s passivating barrier. The other coating layer allows the formation of galvanic element once the sheet is exposed to electrolyte or moisture. This exposure results in the flowing over of zinc ions and corrosion protection of exposed steel. It also helps protect the steel’s trimmed edges and scratches.

Here’s a table showing the EN 10142 equivalent of AZ150 galvalume steel coil thickness.

- 0.150 ± 0.11 mm

- 0.120 ± 0.10 mm

- 0.100 ± 0.09 mm

- 0.90 ± 0.08 mm

- 0.80 ± 0.08 mm

- 0.70 ± 0.08 mm

- 0.60 ± 0.06 mm

- 0.50 ± 0.06 mm

AZ150 galvalume is suitable for buildings or other facilities in extreme environments. It is extremely corrosion-resistant and weather-resistant and can reach a service life of more than 10 years.