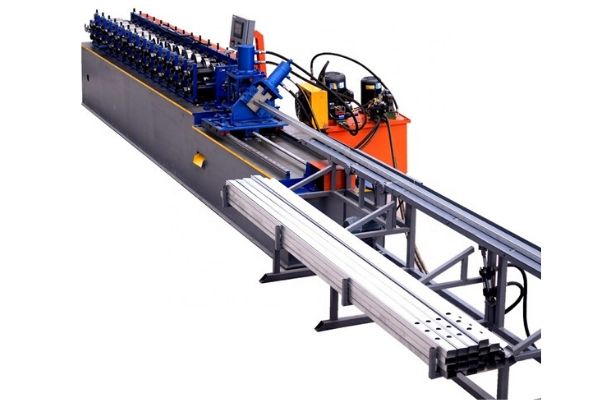

The Introduction of the Cable Tray Roll Forming Machine:

Cable tray roll forming machine is a kind of equipment that integrates many technologies including such as leveling, punching/cutting, automatic conveying (automatic blanking-optional), forming, and so on.

The whole production assembly line is composed of an unwinding system, leveling system, punching/cutting system, automatic conveying system, forming system, electric control system, and other parts.

The cable tray roll forming machine adopts a double-sided cantilever structure, and the punching machine completes the tasks of punching and cutting of the annular ribs or different holes at the bottom of the tray.

The original material is fed into the main forming machine by the feeding table.

Through electrical control, the machine equipment automatically moves and adjusts to produce cable tray finished products of different widths and heights.

The cable tray roll forming machine is a non-standard customized production assembly line, which can form the cable tray at one time.

The main forming machine has adopted a double-cantilever combination adjustable form, without changing the roller when adjusting the specifications of the products, which means that a set of rollers can complete the formation of a cable tray with any specification.

After a long period of time, the cable tray roll forming machine has perfected its details.

At present, the design is reasonable, the price is moderate, the operation is easy to understand, the stability is high, and the yield is high.

Cable Tray Manufacturing Process:

Uncoiler → Leveler → Servo feeder → Punching equipment → Storage device → Forming host → Cutting device → Discharging device

The Main Features of the Cable Tray Roll Forming Machine:

- The cable tray roll forming machine is simple in structure, beautiful in appearance, and reasonable in configuration, which is not only simple and convenient for operation, but also excellently suitable for mass production in factories.

- The important parts and components of the machine are adopted from the most well-known enterprises at home and abroad, thus in this way effectively ensuring the overall performance of the cable tray roll forming machine.

- Advanced design and manufacturing have significantly mechanized and modernized the production of cable tray, which has greatly improved the efficiency of production and has immensely saved the labor costs.

- The noise of the cable tray roll forming machine is low, which has met the needs of green, environmental protection, and energy-saving production.

The Advantages of Cable Tray Roll Forming Machine:

- The electronic control system of the machine is controlled by PLC, and diverse safety protections are set up during daily production.

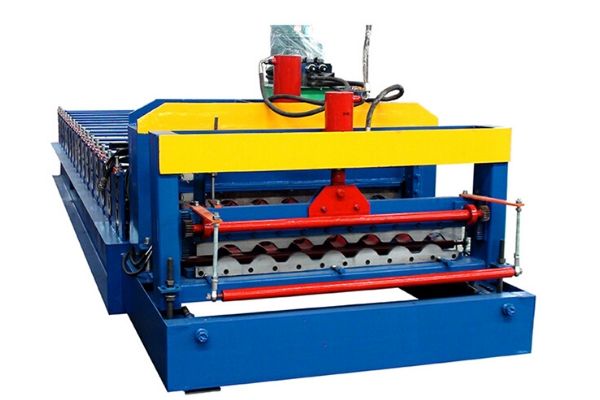

- The body of the machine is made of welded steel plate. The machine has already been tempered for eliminating internal stress and avoiding the deformation of itself.

- The forming frame is made of cast iron which has been tempered, with high strength and long service life.

- The material of the shaft of the roller is 40Cr, having experiencing quenching and tempering, realizing the hardness of HB280.

- The material of the forming mold is GCr15, having quenching treatment, with the hardness of HRC56-62℃.

- The structure of the transmission adopts gearbox transmission. Each forming frame is equipped with a gearbox, which can ensure that the machine runs overtime, operates with high intensity, and has a long service life.

Points needing attention when operating the cable tray forming machine:

Every time before turning on the cable tray roll forming machine, the rotating part of the machine should be filled with lubricating oil.

The main engine chain and sprocket should be refueled once a month, and the reducer should also be refueled once a month to reduce the damage to the machine.

The punching machine must be run empty first for testing.

Check whether the advance and retreat of the oil cylinder and the cutting and resetting function of the cutting device are normal, and install the chain cover.

After the debugging of the whole assembly line of the cable tray roll forming machine is completed, it should be run empty firstly.

If everything is normal, the official production can start. During the process of production, it is strictly forbidden for the steel plate with dead folds and rolls on the head and edge of the board to enter the host machine, so as not to damage the cable tray roll forming machine.

Remember that do not put your hands into the roller to prevent the accidents from happening.

When changing the mold, be sure to stop the motor. Turn the key to stop and remove the key.

The purpose is to prevent accidents during replacement and to prevent someone from accidentally rotating the key during construction.

What should be paid attention to about the operation in winter?

Operating the cable tray roll forming machine in winter, the main resistance comes from the temperature.

The low temperature in winter is everyone’s consensus.

The operation of the cable tray roll forming machine at low temperatures may fail, which affects the efficiency of the production of the cable tray and the quality of the cable tray.

Therefore, the manufacturer can test the temperature that is suitable for the operation of the cable tray roll forming machine in advance and then take according to measures such as heating or preheating the equipment in advance to make it reach the predetermined temperature to avoid the appearance of the machine malfunctions.

When the cable tray roll forming machine is operating in winter, pay attention to safety inspection, including checking the current and voltage before starting, whether the values of the forming machine are within the specified range, and ensuring that the components of the forming machine are not seriously worn, there is no entanglement or looseness in the internal wires.

This is to prevent safety accidents such as string electricity and leakage when the cable tray molding machine is running.

These are mean to prevent the occurrence of safety accidents such as electric string leakage and electric leakage when the cable tray roll forming machine is in operation.

The Classification of Cable Trays:

In modern buildings, whether it is an industrial building or a civil building, a lot of necessary cables and wires need to be installed.

The cable tray is for laying cables.

The cable tray is composed of supporting arms, brackets, and some installation accessories.

It is mainly divided into four types of structures, namely grid structure, ladder structure, pallet structure, and slotted structure.