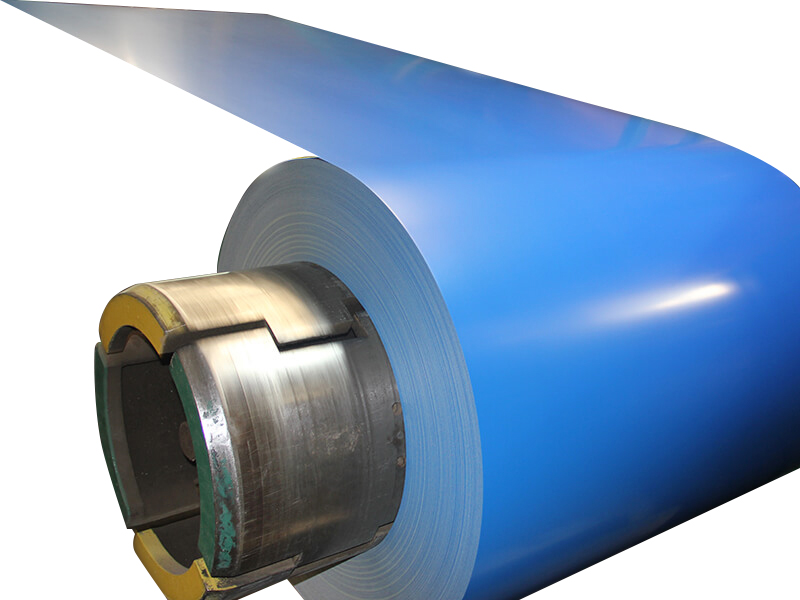

Dx51d Z150 galvanized steel coil is a coating and steel grade designation under the ASTM A653 / A653M requirements or specifications. The direct function of coating thickness is to protect the steel product against atmospheric corrosion.

What is dx51d z150 Galvanized Steel Coil?

Manufacturers describe dx51d z150 material as a mild steel zinc-coating to steel products. Specifically, dx51d is a steel grade characterized by its cold-forming bending and profiling qualities. This steel grade corresponds to the steel number 1.0917.

Consequently, Z150 is the coating designation, and Zinc (Z) is the type of coating applied. However, other types of coating layers available for this steel grade include aluminum-silicon-alloy (AS), aluminum-zinc-alloy (AZ), zinc-magnesium-alloy (ZM), zinc-aluminum-alloy (ZA), and zinc-iron-alloy (ZF).

Under the Z150 specification, galvanized steel coils must have a minimum zinc coating weight of 150 grams per square meter (g/m2) on both sides. The product must pass the triple-spot test (TST).

During corrosion, the zinc coating protects the steel from rusting. When exposed to corrosive environments, the zinc coating will corrode instead of the steel. Hence, the common logic for zinc-coating is that a thicker zinc coating corresponds to a more significant layer of protection.

What does z150 mean?

Z150 in Dx51d Z150 Galvanized Steel Coil is the actual coating designation.

Z in Z150 denotes the zinc-coating of the product; manufacturers supply the steel product with zinc coatings or simply zinc-coated. Meanwhile, the numeric 150 represents the product’s minimum zinc coating weight of 150 g/m2 as determined by the triple-spot test (TST).