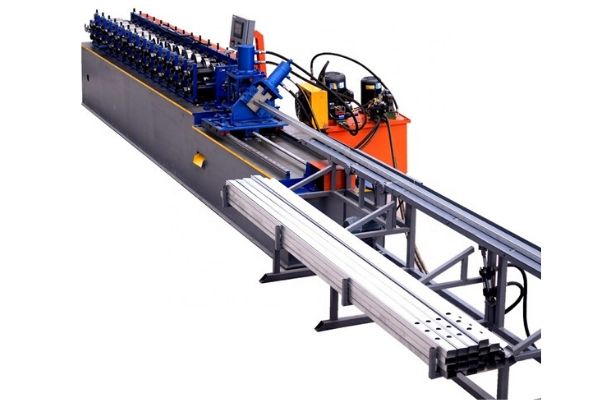

C Purlin Roll Forming Machine:

C purlin roll forming machine is a set of a single-roll forming unit whose roll can produce various specifications of C purlin finished products. C purlin roll forming machine is mainly composed of a passive loading rack, leveling device, punching device, cutting device after forming, hydraulic station, computer control system, etc.

C purlin roll forming machine adopts automatic flying saw punching, being easy to operate. The finished C steel purlins rolled by the C steel machine have the advantages of good tension, bending and compression properties, good straightness, full-automatic fixed-length cutting, automatic punching, a high degree of automation, and quick and easy installation.

C purlin roll forming machine products can be used as the main force-bearing structure of large and medium-sized industrial civil buildings, such as roof load-bearing load and wall flat support of factory buildings, warehouses, machine garages, exhibition halls, theaters, stadiums, and market flower sheds.

The strip steel is fed from the rear of the equipment and pressed into C steel by various pressing rollers and sent out from the head. After gradually improving the production process, the automatic control of the whole process was finally achieved, which dramatically improved the production efficiency and increased the technical content and added value of customer equipment.

The improvement process is completed in three steps.

The first step is adding a length measuring device and flying saw. When the pressing length reaches the set length, the flying saw acts to automatically cut the profile.

The second step is to add a hydraulic punching device for punching side holes. Four holes are punched at the same time, and the flying saw is cut from the middle, thus forming two side holes for the head and tail of two adjacent sections of C steel.

The third step is to add a middle hole punching device. In the process of strip steel pressing, the middle holes are punched out according to the distance set by the user, with a maximum of 16 middle holes which can be punched.

The fourth step is to change the 4-hole punching die for the side hole into a 2-hole die for the new C steel that requires double holes in the middle of the profile. Modify the side hole punching program, so that the side hole punching equipment can punch double holes in the middle, and the hole distance should be set by the users.

The maximum number of double holes can be 8 groups so that it can meet the requirements of all C steels.

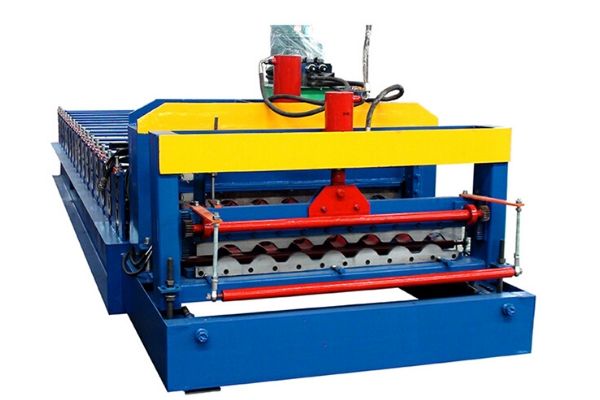

Z Steel Purlin Roll Forming Machine:

Z steel purlin roll forming machine is a kind of equipment for making steel structure purlins. There are three types of shearing methods, namely die-cutting, flying saw cutting, and stepless cutting. This Z steel machine is a cold-bending forming unit that can produce a variety of Z steel products by rolling through the roller wheel.

Equipped with imported high-precision computer control systems, imported electrical components, and assembly language which bring convenience to users from various countries, it is simple and easy to operate.

The automatic flying saw cutting Z steel purlin roll forming machine is used to produce Z purlins of steel structure buildings. It is made of a high-strength steel plate and is formed by cold bending. It has the characteristics of uniform wall thickness, excellent cross-sectional performance, and large compressive strength.

It is usually used in large-scale steel structure workshops to support the overall frame. As the purlin of steel structure, it increases the stability of the steel structure. Overlapping continuous purlins, the unequal flange design, porous connection, are strong and reliable.

Adopting high-hardness flying saw cutting method, without changing the mold, it is fast in cutting and simple in operation. Using chain transmission, the transmission ratio is relatively fixed. The transmission distance is long, the bearing capacity is large, and the transmission noise is small.