All steel products for commercial, agricultural, mechanical, and industrial use are subject to ASTM standard specifications. Zinc-coated (galvanized) steel coil by the Hot-Dip Process like Z120 indicates the coating thickness.

What is the Z120 galvanized steel coil?

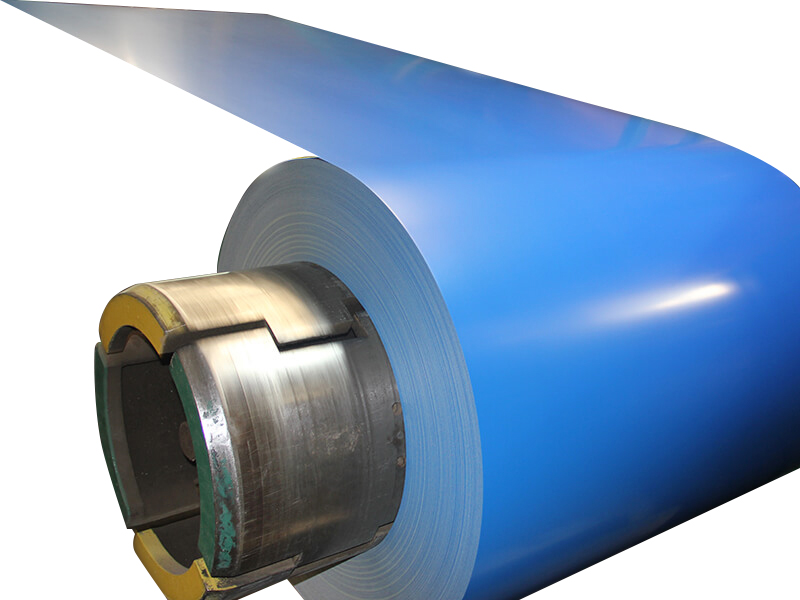

Galvanized steel coil with Z120 grade is coated with zinc to make it more durable. The process works by immersing the coiled steel plate in the galvanizing tank that is filled with molten zinc. By subjecting the thin steel plate to a continuous galvanizing process, the result is a galvanized coil. This type of steel offers better formability and good painting adhesion during commercial or construction use. Another way to produce galvanized steel plates is through a hot-dipping procedure. In this method, it is crucial that right after leaving the tank, the steel plate undergoes 500°C heat treatment to form an alloy film coating.

The galvanized steel coil is popularly used in ventilation ducts, floor panels, automobiles, sandalwood strips, color-coated substrates, and three-dimensional parking garages. The industries that heavily rely on it are transportation, agriculture, solar, and appliances.

The primary advantage of galvanized steel is the strong resistance against corrosion. The zinc coating protects the underlying steel against the harsh elements of the environment.

What does Z120 mean?

Z120 is a coating designation that shows that the approximate coating thickness of both sides is 120 g/m2 or 36 g/m2 (triple-spot test)/90 g/m2 (single-spot test). Because of the changing condition during the continuous hot-dip process and certain variables, the zinc coating is not equally divided between the sides’ surfaces or spread evenly from one edge to the other. The zinc coating thickness is calculated by dividing the zinc coating mass on two sides (g/m2) and the zinc density (g/cm3).