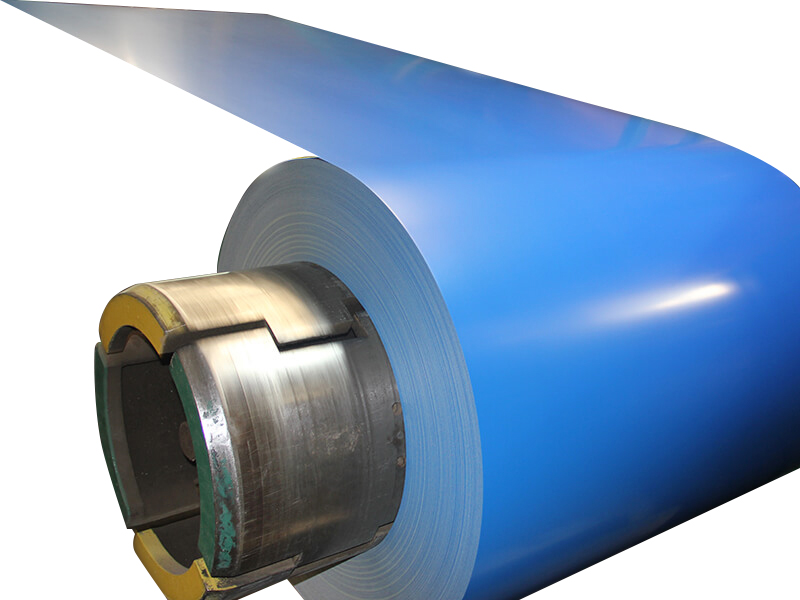

Dx51d z200 refers to galvanized steel coil that undergoes a continuous hot-dip galvanizing process. This method offers the steel coil broad protection from corrosion by adding a tight bond between the steel and the coating.

Dx51d z200’s zinc coating is suitable for bending and welding with high resistance to a corrosive atmosphere. This galvanized steel coil is excellent for outdoor and indoor applications for buildings, structures, and household appliances. The high coating of pure zinc and low carbon for base material offers longevity to the designs.

Its formability and ductility make it a widely used material for roofing, walling, windows, shutters, refrigerators, watch rooms, booths, rolling doors, gates, door frames, sliding doors, ceilings, communication pipelines, and many more.

What does z200 mean?

z200 refers to the galvanized steel coil’s coating designation. Both surfaces of the steel coil have a triple spot test of 200 g/m2 and a single spot test of 170 g/m2. The guidance value for coating thickness per surface is 14 μm with a range of 10 to 20 and a density of 7, 1 g/cm3.

The coating conditions do not impact the quality of the galvanized steel coil, which could be in the form of many zinc crystals, no spangles, or without the presence of zinc crystals. The surface quality of z200 is X for the letter A under Normal spangle (N). The Minimized spangle (M) has a triple X under the letters A, B, and C.

Solidifying the zinc coating naturally leads to the formation of zinc crystals or without spangle as in the case of Normal spangle. Few or fewer visible spangles are the production of intervention in the solidification process of zinc coating, as shown in the results of the Minimized spangle.