Different types of hot-dipped galvanized steel coils are produced, one of which is DX51D Z100. Learn more about it here.

What is a DX51D Z100 galvanized steel coil?

The DX51D Z100 steel is very flexible and pliable. It is used in complex solid dispersion components and is BS EN 10346:2015 compliant.

Chemical compositions of DX51D are ≤0.18% carbon (C), ≤0.50% silicon (Si), ≤1.20% manganese (Mn), and ≤0.12% phosphorus (P), and ≤0.045% sulfur (S). As for mechanical properties, the tensile strength ranges from 270 to 500 MPag, while the minimum elongation is 22%. The steel number is 1.0917.

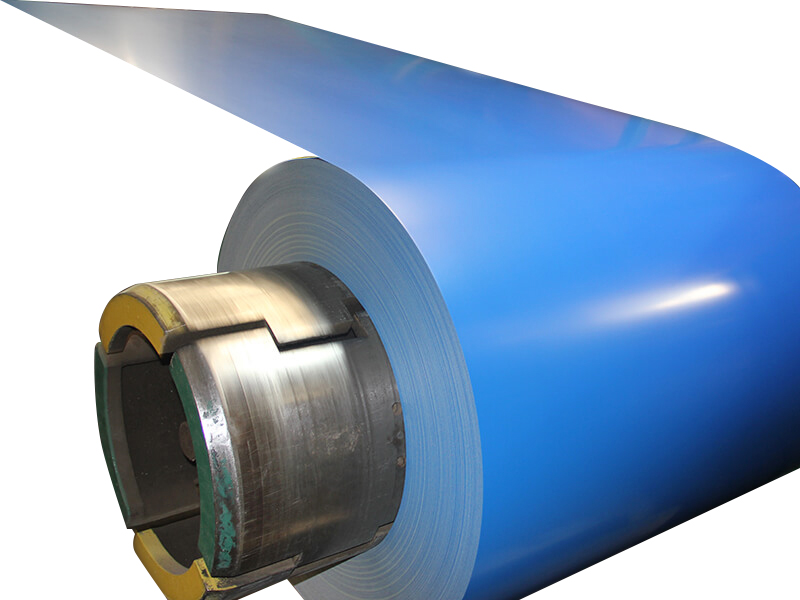

DX51D steel coils are produced in 950 to 1250 mm broad coils and 0.4 to 1.6 mm thick. The coil’s inner diameter is 600 mm, and its outside diameter can reach 1300 mm. The maximum coil weight is 8 tons. Cut edges are provided on the coils (mill edges are also possible).

DX51D steel coils are widely used in various steel products such as roofing, window profiles, drains and ventilation systems, road barriers, bridges, and home appliances.

What does Z100 mean?

Z100 indicates the weight of zinc coating used on the coated steel coil. It is expressed in grams of zinc or aluminum/zinc per square meter (g/m2).

Each coating has a predetermined thickness and is tailored for a particular application. Z100 has the thinnest coverage at 7 micrometers and is exclusively intended for use indoors. Its minimum total coating mass applied on both steel is 100 g/m2.

Continuous hot-dip galvanizing provides a broad protective spectrum from Z100 to Z600 and a strong link between the coating and the steel. Because of their characteristics, zinc coatings are ideally suited to forming and demanding corrosive atmospheres.