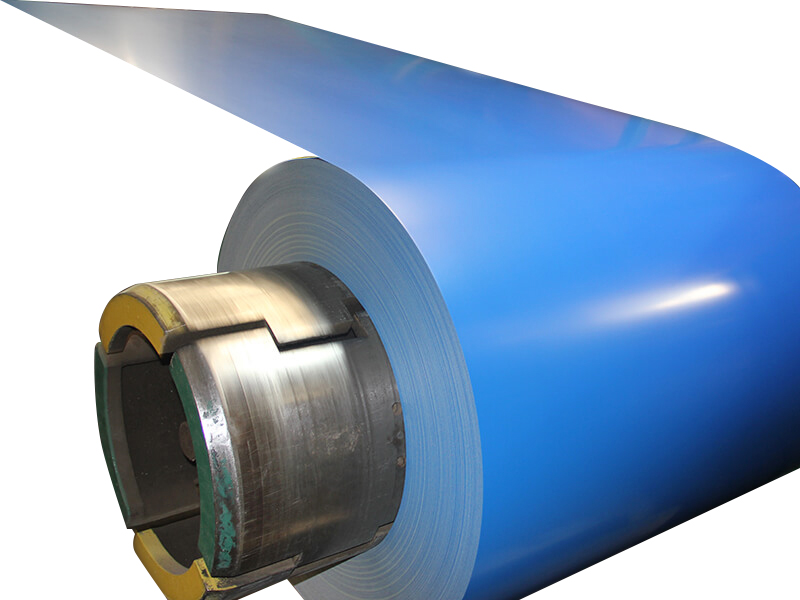

Color-coated aluminum coils are color-coated on aluminum coil. Common fluorocarbon color-coated aluminum and polyester color-coated aluminum are widely used in aluminum-plastic panels, aluminum veneers, and aluminum honeycomb panels. Aluminum ceiling, roof surface, leftovers, cans, and electronic products. Its performance is very stable and not easy to corrode. After special treatment, the surface can reach 30 years of quality assurance. The weight per unit volume is the lightest among metal materials.

The color-coated aluminum coil is processed by washing, chromizing, roll coating, baking, etc., and the aluminum coil surface is coated with various color paint coatings.

Differences between Prepainted Aluminum Coil and Prepainted Steel Coil

| Difference | Color Aluminum Coil | Prepainted Steel Coil |

|---|---|---|

| Durability | 25-40years | 15years around |

| Weight | Density: 2.71g/mm3 Lighter, around one-third of Steel | Density: 7.85g/mm3 |

| Strength & Rigidity | In Middle Level, good enough for house construction | Better |

| Appearance | Much more smooth than steel | smooth |

| Anti-thunder property | Anti-thunder | No anti-thunder property |

| Tile forming | It has good welding property and keep physical property in low temperature | It has cold shortness. In low temperature, it is easy to break. |

| Cost performance | High cost performance. Light weight,water-proof, easy bending, good stereoscopic vision; | Weight is three times of aluminum; middle level water-proof property; |

| Recovery Value | High recovery Value, 70% of original value | No recovery Value |

| Feature | The meters per ton is three times longer than Steel; | Comparative cheaper price |

The difference between polyester and fluorocarbon coating (how to choose different coatings):

Polyester coating (PE)

It is a kind of anti-UV ultraviolet coating. The polyester resin is a polymer containing an ester bond in the main chain as a monomer. Ton acid resin is added. The ultraviolet absorber can be divided into matt and high gloss series according to the gloss. Especially suitable for interior decoration and advertising boards.

Fluorocarbon coating (PVDF)

It is made by mixing fluorocarbon resin with fluoroalkene as the basic monomer, pigment, alcohol ester solvent and additives. After baking at high temperature to form a film, the molecular structure in the coating is tight, and it has super weather resistance. Fluorocarbon coatings can be divided into traditional fluorocarbon and nano-fluorocarbon coatings according to the surface film-forming structure. Especially suitable for decoration and display of indoor and outdoor decoration, commercial chains, exhibition advertisements in public places.

Coating thickness: PVDF (fluorocarbon)≥25micronPOLYESTER(polyester)≥18micron;

Glossiness: 10-90%;

Coating hardness: greater than 2H;

Adhesion: not less than level 1;

Impact resistance: 50kg/cm, without peeling paint and no cracks. The color of Polyester can be used for 20 years, while fluorocarbon can be used for 30 years without discoloration.

The Characteristic of Color Coated Aluminum Coil

Flatness: No composite high-temperature indentation on the surface. There is no residual stress on the board surface, and it will not deform after shearing.

Decorative: Coated with wood grain and stone grain, it has a realistic sense of real material and a fresh natural beauty. The patterns are made at will, giving customers a wide range of personality choices, which can enrich the humanistic connotation of products and give people more beautiful enjoyment.

Weather resistance: The paint pattern made by coating and baking at high temperatures has high gloss retention, good color stability, and minimal change in color difference. The polyester paint is guaranteed for 10 years and the fluorocarbon paint is guaranteed for more than 20 years.

Mechanical: The use of high-quality aluminum, plastics, and adhesives, using advanced composite technology. The product has the bending and bending strength required by the decorative board. In the four seasons, the changes in wind pressure, temperature, humidity, and other factors will not cause bending, deformation, and expansion.

Environmental protection: Resistant to salt and alkali acid rain corrosion, it will not corrode and produce poisonous bacteria, does not release any toxic gas, does not cause corrosion of keel and fixed parts.

Flame retardancy: not less than B1 level according to national regulations.

Material grade of aluminum coil:

1000 series:

The 1000 series aluminum plate is also called the pure aluminum plate. Among all the series, the 1000 series belongs to the series with the most aluminum content. The purity can reach more than 99.00%. The price is relatively cheap. Most of the circulation in the market is 1050 and 1060 series.

2000 series:

2A16 (LY16) 2A06 (LY6) 2000 series aluminum plate is characterized by high hardness, of which the content of copper is the highest, about 3-5%.

3000 series:

Mainly represented by 3003 3003 3A21. It can also be called anti-rust aluminum plate. The production process of the 3000 series aluminum plate of our nation is excellent. 3000 series aluminum plate is made of manganese as the main component, with content between 1.0-1.5. It is a series with good anti-rust function.

4000 series:

The aluminum plate represented by the 4A01 4000 series belongs to the series with the higher silicon content. The silicon content is usually between 4.5-6.0%. It belongs to construction materials, mechanical parts, forging materials, welding materials, with a low melting point, and good corrosion resistance.

Product description: Having the characteristics of heat resistance and wear resistance.

5000 series:

With 5052.5005.5083.5A05 series as representatives, the 5000 series aluminum plate belongs to the more commonly used alloy aluminum plate series, and the main element is magnesium, and the magnesium content is between 3-5%. It can also be called aluminum-magnesium alloy. The main characteristic is low density, high tensile strength, and high elongation.

6000 series:

with 6061 as a representative, it mainly contains two elements of magnesium and silicon. 6061 is a cold-processed aluminum forged product, which is suitable for applications that require high corrosion resistance and oxidation.

General characteristics of 6061: Having excellent interface characteristics, easy coating, high strength, good usability, and strong corrosion resistance.

The advantages of Color Coated Aluminum Coil:

- Light texture, easier to shape

- Corrosion resistance Because it has a tight oxide film on its surface, it has strong adhesion, oxidation resistance, acid resistance, alkali resistance, corrosion resistance, decay resistance, and ultraviolet resistance.

- Good temperature resistance, the melting point of aluminum is 660 degrees, the general temperature can not reach his melting point

- The board has extremely high strength, which can be cut, slitted, balanced, drilled, connected, fixed and compressed at the edge.