Definition:

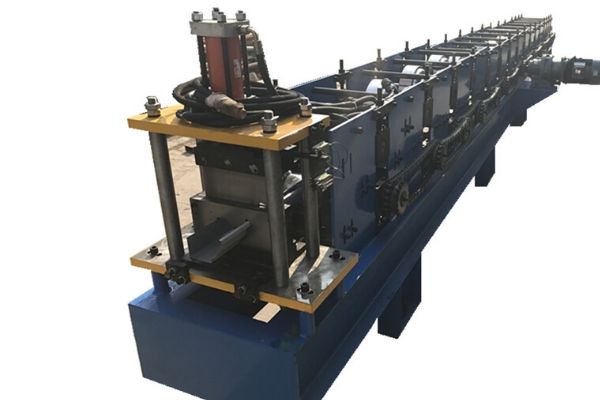

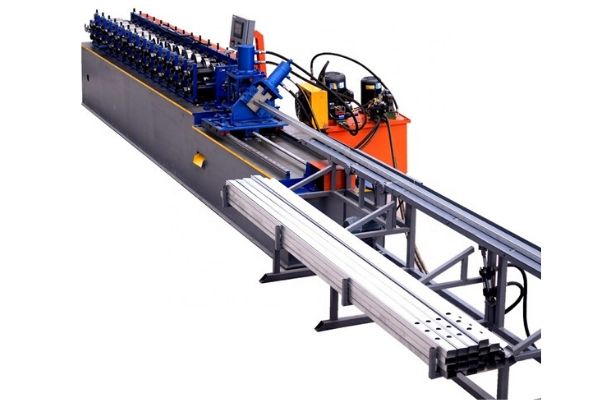

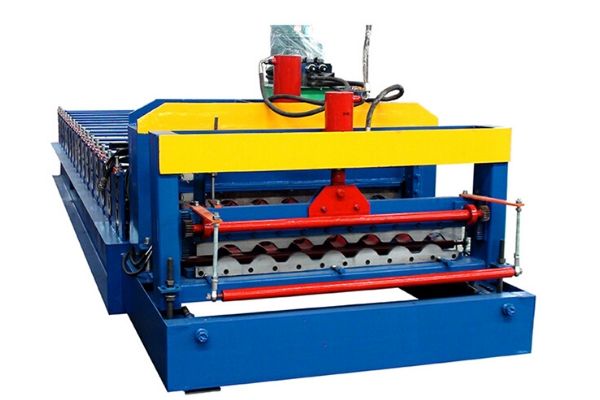

Double-layer roll forming machine is a production machine composed of unwinding, forming, post-forming cutting. Its color plate is flat and beautiful in appearance, uniform in paint texture, high in strength and durable, and is widely used in industrial civil buildings, such as the roofs and walls of factories, warehouses, gymnasiums, exhibition halls, theaters and etc. The components of the tile pressing machine include the whole machine of the color steel tile pressing machine, the PLC computer control system, the hydraulic pump station system, and the fully automatic post-shear system.

Product Features:

- The double-layer roll forming machine applies high-level automatic control software to achieve the informationized management of production.

- The automation control system of the entire unit uses a highly integrated network, which makes the automation system better.

- A double-layer roll forming machine can press two types of tiles. Different models such as 840/900, 840/850, 860/910, any two models of them can be combined casually. The biggest advantage is that it occupies a small area which saves space, and is fully automatic computer-controlled. However, only one type of board can be produced during operation, which is equivalent to two single-layer roll forming

- The machine can set multiple sets of different data to produce different lengths of finished products.

The correct feeding operation method of the double-layer roll forming machine:

When feeding the double-layer roll forming machine, the first thing we should pay attention to is that the flat color steel plate material should be aligned with the pressure roller of the roll forming machine, and both layers need to be aligned, to ensure that they will not move when feeding.

When the double-layer roll forming machine is on, we can press the color steel plate by hand to end the task of pushing the feed material while ensuring a safe distance from the press roller of the roll forming machine. If it is found that the color steel plate is obstructed or the material cannot be fed, we must shut down the mechanical equipment in time and then adjust the color steel plate.

After the adjustment is completed, follow the steps just now. When collecting, do not pull the color steel plate by hand. Let the color steel plate fall actively, and then you can retract it by hand after its dropping. If we pull it by hand when it is not finished, it will cause the deformation of the color steel plate behind, which will generate a lot of waste and also will waste a lot of material.

The Specification of Double Layer Roll Forming Machine:

Product: Double Layer Roll Forming Machine

Tile Type: Colored/Glaze Steel

Voltage: 380V 50Hz 3phases

Production Capacity: 15-20m/min

Weight: 10.5Tons

Power(W): 5.5KW+5.5KW

Thickness of Material: 0.3-0.8mm

Dimension(L*W*H): 9500*1500*1650MM

Roller Material: 45# steel with hard chromed 0.07MM

Shaft Material: 45# steel processing

Cutting System: Hydraulic guide pillar stop cutting

Cutting Blade Material: Cr12Mov

Thickness of Middle Plate: 16mm

Price: $15,000.00 – $21,000.00

Inspection and Maintenance of the Double-layer Roll Forming Machine:

1. Perform regular inspection and maintenance of electrical equipment according to regulations. Unused electrical equipment wiring should be removed.

2. In the event of a power outage, if there is an electric body less than 0.8 meters away from the inspection staff, an insulation material shall be used for reliable temporary shelter.

3. When it is found that the conductive part of the double-layer roll forming machine is grounded, before the power supply is blocked, it is not allowed to come close except to rescue the electric shock. It should be 3.8 meters away from the electrically shocked person and 1.5 meters away from in the room to avoid stepping voltage damage.

4. Electricians must know the types and functions of electrical circuits and electrical equipment in the workshop. If they do not fully understand the functions of electrical equipment, risky work is prohibited.

5. The electrician should check the condition of the motor, cable, electric console and other equipment as scheduled. Any problems found during the inspection must be dealt with in time. When checking the temperature of the motor, firstly assure that there is no electricity, and then test with the back of the hand.

6. Except for temporary construction electricity or temporary measures, no temporary wires shall be installed, and lights shall not be hung randomly. The original electrical circuits of switches and sockets used in instrumentation tools, welding machines, etc. shall not be changed without authorization.

Reasons for Defects in the Production Process of Double-layer Roll Forming Machine:

- The bag-shaped wave is mainly due to the lateral tensile stress and lateral strain generated during the bending process of the plate, and the strain of the sheet material in the thickness direction is relatively small. According to the relationship between the material deformation, the deformation will be concentrated. The parts contracted and deformed along the longitudinal direction.

- There are many reasons for the longitudinal bending of the double-layer roll forming machine. One of the most important reasons is that the edges of the cross-section are subjected to the tensile force when bending the side, which tries to stretch the entire cross-section longitudinally, but is not enough to lengthen the entire rigid section, resulting in the phenomenon that the front end of the rolled piece bends up or down.

- The edge wave is a bag-shaped wave and is a common defect. Its production is mainly the synthesis of two effects: one effect is the same as the mechanism of the bag wave. It is because the material in the bending part of the cross-section is subjected to transverse tensile stress, which produces transverse tensile strain. In the case where the strain in the thickness direction is not large, longitudinal shrinkage occurs, and the edge portion generates edge waves due to compression stress. The second is that the material at the edge part is stretched and sheared to become longer under the action of external force, and then compressed and sheared again to produce plastic deformation causing edge waves. These two effects are superimposed on each other to form a side wave.