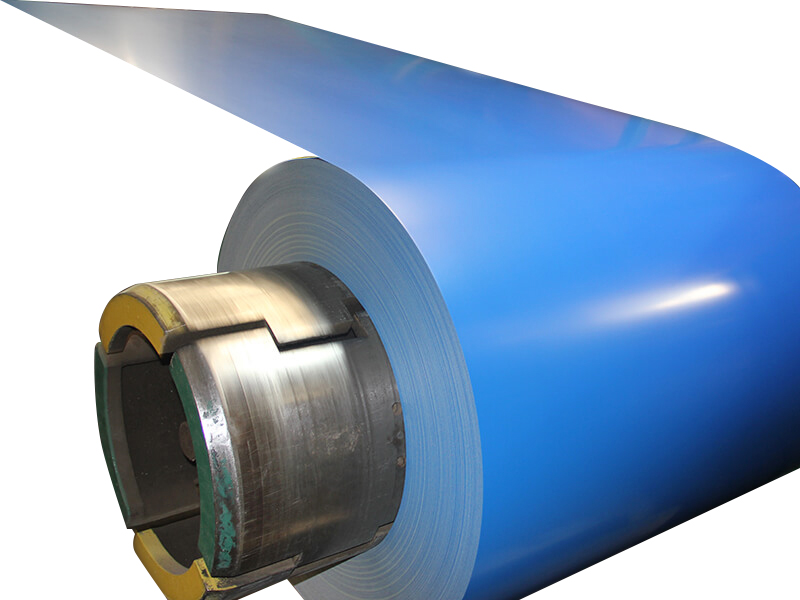

G40 galvanized steel coil is a common zinc coating weight or designation that is directly proportional to the expected life service of the steel product.

What is G40 Galvanized Steel Coil?

Galvanized steel coils are covered in a zinc coating to provide resistance against corrosion. G40 Galvanized steel coil is a zinc coating designation or a requirement specified in the A653 Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron AlloyCoated (Galvannealed) by the Hot-Dip Process.

Under the G40 coating designation, the coating weight on the steel must have a triple-spot test (TST) average minimum of 0.40 ounces per square foot on both sides or 0.20 ounces per square foot on each side. Meanwhile, for a single-spot test (SST), both sides of the steel must have an average minimum coating weight of 0.30 ounces per square foot.

G40 protective coating prevents moisture from reaching the steel structure, which increases the steel’s resistance to corrosion. Such extend the expected lifespan of the steel product. G40 is an average coating weight, therefore serving moderate protection.

General rules state that a heavier coating layer also means a longer lifespan for the steel product. However, site conditions such as temperature, exposure, and humidity remain the most critical factors.

What does G40 mean?

Coating designation G40 stands for the type of coating and the weight of the applied coating layer.

The alpha letter ‘G’ indicates that the coating is galvanized, meaning zinc-based. Meanwhile, the numeric ‘40’ stands for the weight of the zinc on the surface of the steel sheet. Manufacturers use the unit ounces per square foot (oz/ft2) to measure the weight of the zinc.

In short, a G40 labeled galvanized steel coil means there are 0.40 ounces of zinc applied per square foot of the steel surface.

Aside from G40, other common zinc-coating designations are G30, G60, and G90.