Definition:

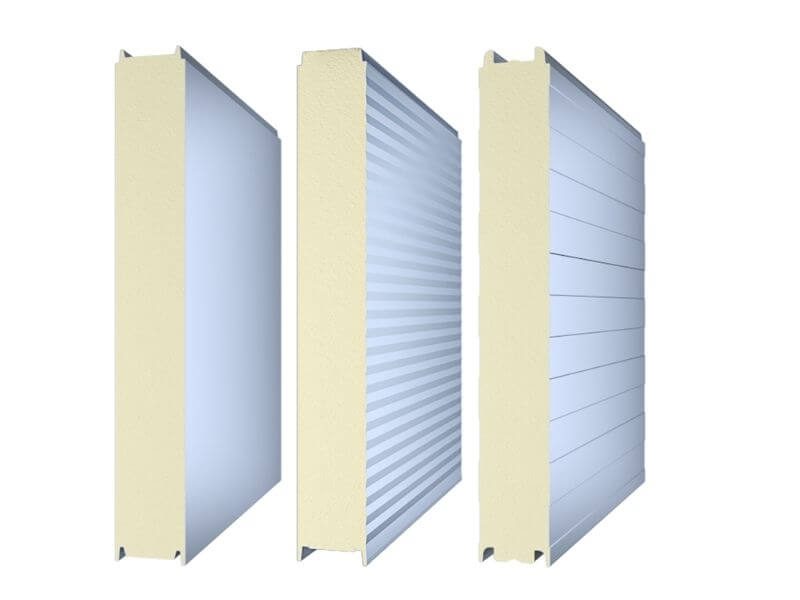

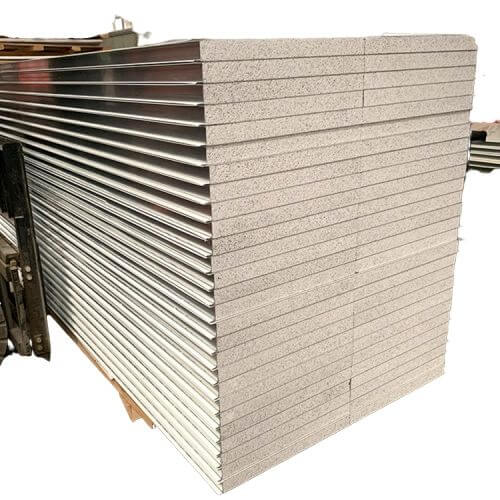

The inner and outer sides of the PU sandwich panel are glass steel plates, and the rigid polyurethane foam of the sandwich layer is compounded by German vacuum technology and high pressure. The surface of the sandwich panel is smooth and clean, and dirt can be easily removed. The entire panel is brightly colored and has excellent gloss retention.

PU Sandwich Panel Specification:

| Product | PU Sandwich Panel |

|---|---|

| Steel Sheet Thickness | 0.4-0.7mm |

| Core Material Thickness | 40mm 50mm 60mm 75mm 100mm 120mm 150mm 200mm |

| Density | 40kg/m3 |

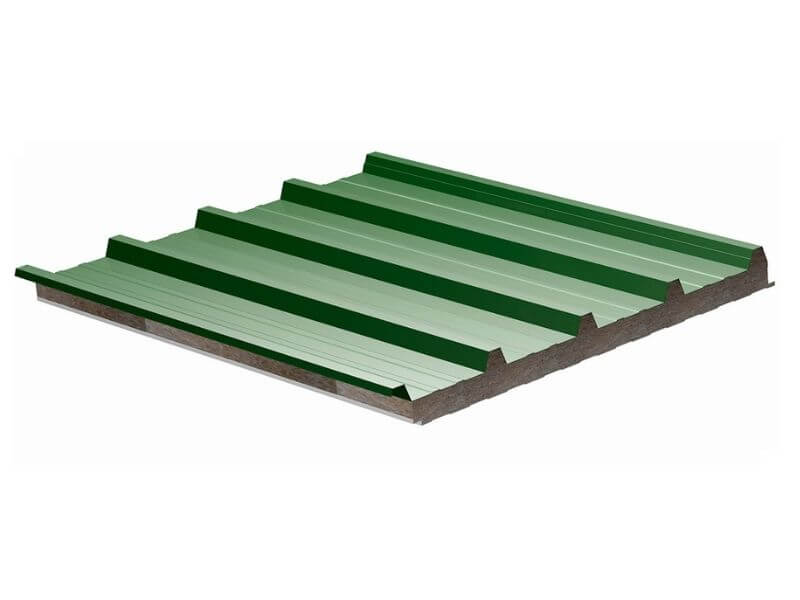

| Effective Width | Wall:400-1120mm Roof panel: 1000mm |

| Length | Less than 11.8m (container inner length) |

| Thermal Conductivity | 0.019-0.023w/m.k |

| Moisture Permeability Coefficient | ≤3.34Ng/Pa/m.s |

| Water Absorption | ≤0.5g/100cm2 |

| The Compression Strength | ≥220KPa |

| The Bending Strength | ≥2450KN/m2 |

| Fireproof Grade | B1 B2 |

| Application | Insulation / refrigeration / dry truck compartments, large-span structural roofs, walls, thermal insulation (or fire protection) workshops, purification workshops, high- and mid-range combination houses, cold storage, container houses, etc. |

| Price | $5-15/ Meter |

| HS Code | 73809000 |

Advantages of PU Sandwich Panel:

1.Efficient insulation.

Because the thermal conductivity of the foaming agent used in the PU board is much lower than that of air (good insulation), the insulation performance of PU rigid foam is better than pure air materials such as mineral wool, glass fiber, and polystyrene. In addition, its unique closed-cell and high gas diffusion resistance make it have excellent long-term insulation performance, which can last 20-50 years or more.

2.Corrosion resistance.

The closed-cell structure of polyurethane rigid foam and the surface material used make it have excellent air resistance and moisture resistance and can be made into a mosaic structure during the molding process, easy to assemble. It does not require an additional insulating layer to protect it from moisture and thus does not require many insulating layers. Other insulating materials cannot achieve these characteristics.

3.Wide, light, and thin-walled.

Since PU rigid foam is used as a structural material at the same time, the overall structure has the advantages of a lightweight, large span, and high load. Compared with other insulating materials, polyurethane rigid foam has insulating properties. Therefore, thinner polyurethane sandwich panels can meet building energy requirements and allow thinner panels to be used during construction, saving building space.

4.Stable quality and high production efficiency.

Nowadays, in the case of a sharp increase in demand, in addition to the convenience of quality control, the production line of the factory producing polyurethane sandwich panels has also brought a good economy and competitiveness.

5.Good weather resistance and easy installation.

PU sandwich panels are prefabricated at the factory and can be used directly for building installation without additional processes and structures. And there is no need to consider whether changes to planning production.

The product is a synthetic material with excellent properties. It has the advantages of high specific strength and low thermal conductivity. It is mainly used as an insulating material, followed by structural materials.

Application of PU Sandwich Panel:

PU Sandwich Panels are widely applied in insulation/refrigeration / dry truck compartments, large-span structural roofs, walls, thermal insulation (or fire protection) workshops, purification workshops, high- and mid-range combination houses, cold storage, container houses, etc.

FAQ:

What are the PUF panels?

Polyurethane Rigid Foam Sandwich Panel (PUF) is a polymer thermosetting thermal insulation heat-resistant synthetic material with excellent performance. It is currently the best thermal insulation material in the market with low thermal conductivity, good thermal insulation effect, and convenient construction. There are several major advantages and features:

- Lower thermal conductivity (0.019 ~ 0.027).

- Unique construction method.

- It has good adhesion.

- It has good fire and temperature resistance.

- It has the characteristics of breathability and impermeability.

- Good crack resistance.

What are insulated metal panels?

The insulated metal panel is directly prepared anodized layer (aluminum oxide film) on the surface of the metal substrate (aluminum substrate/aluminum alloy substrate). The aluminum oxide film has good electrical insulation and can be used as an insulating layer. Because the aluminum oxide film is directly used as the insulating layer of the insulating metal panel, the aluminum oxide film has high electrical insulation, excellent heat dissipation characteristics, and good thermal shock resistance. Therefore, such an insulated metal panel has strong heat dissipation capacity and high reliability and is one of the ideal substrate materials.

Regarding sea shipping from Japan

you can estimate the container shipping costs from FreightPaul, the digital freight forwarder in Japan.

Types of Sandwich Panels:

- In terms of core materials:

- Polystyrene sandwich panel, namely EPS sandwich panel (currently the most widely used variation on the market);

- Extruded polystyrene sandwich panel, namely XPS sandwich panel;

- Rigid polyurethane sandwich panel, namely PU sandwich panel;

- Three polyester sandwich panels, namely PIR sandwich panels;

- Phenolic sandwich panel, namely PF sandwich panel;

- Rock wool sandwich panels, namely RW sandwich panels.

- In terms of the panel:

- Metal panels.

- Non-metal panels