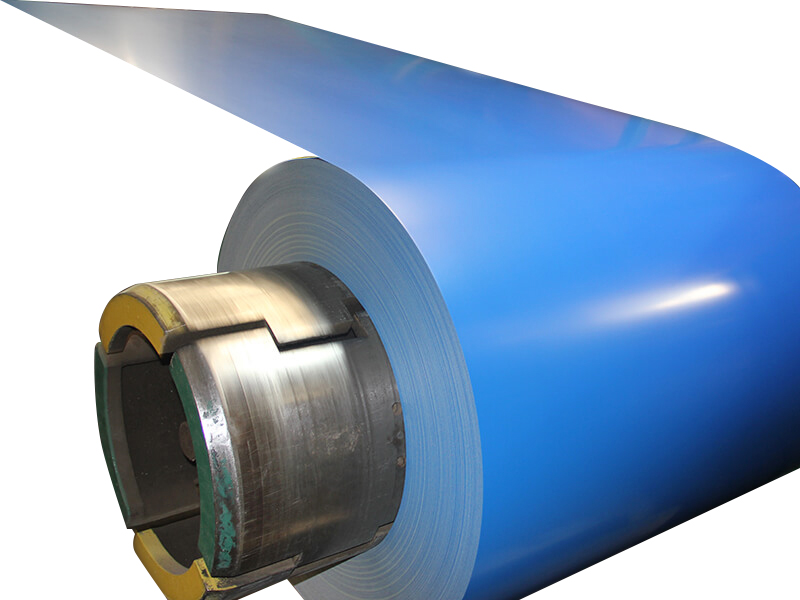

The pre-painted steel sheet is based on cold-rolled steel sheet and galvanized steel sheet, after surface pretreatment (degreasing, cleaning, chemical conversion treatment), and coating (roller coating method), a product made by baking and cooling.

The coating structure includes two coats and one bake, two coats and two bakes, etc. The maintenance-free service life can be 10-30 years depending on the ambient atmosphere.

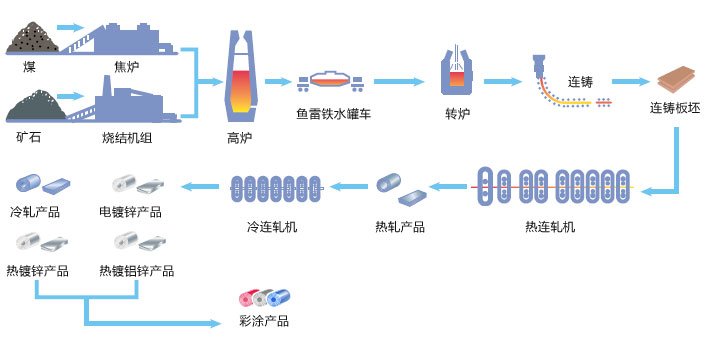

The main production process of the common two-coating and two-baking type continuous color coating unit is uncoiler – stitching machine – pressing roller – tensioning machine – Uncoiling Looper – Alkaline Degreasing – Cleaning – Drying – Passivation – Drying – Beginning Coating – initial coating and drying – topcoat fine coating – topcoat drying – air cooling and cooling – winding work Set – rewinder – (the next roll is packed and put into storage).

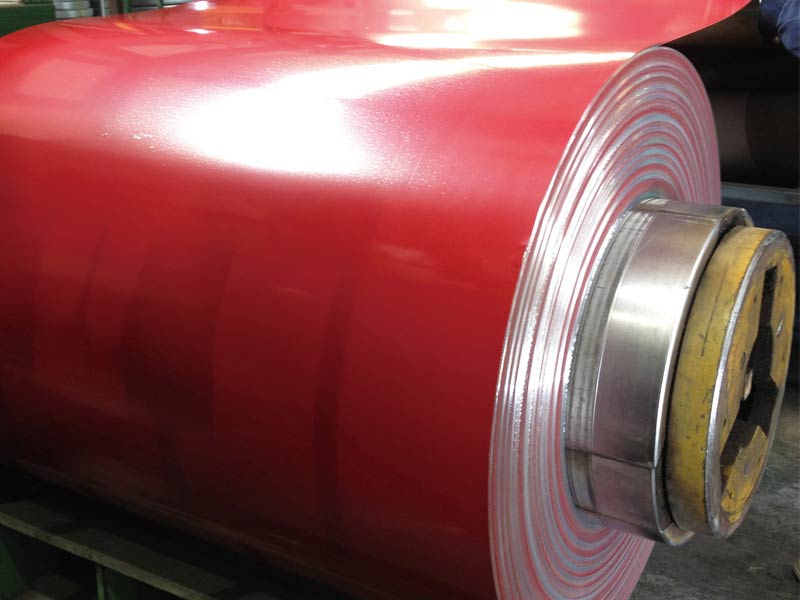

The coating structure of the double-sided two-coated and two-baked color-coated steel plate is shown in the above picture

The upper surface is coated with two layers of paint, and the lower surface is coated with a layer of color-coated steel plate, as shown in the picture above (this kind of back paint is generally not suitable for front use)

Pre-Painted Steel Sheet is a product made of cold-rolled steel sheet, electro-galvanized steel sheet, hot-dip galvanized steel sheet, or galvanized steel sheet after surface degreasing, phosphating, and chromate treatment, and then coated with organic paint and baked. . The commonly used coatings for color-coated steel plates are polyester (PE), followed by silicon-modified polyester (SMP), PVDF, etc. The coating structure is divided into two coatings and one baking and two coatings and two baking. The thickness of the coating is generally 20- 25μ, backside is 8-10μ.