Introduction:

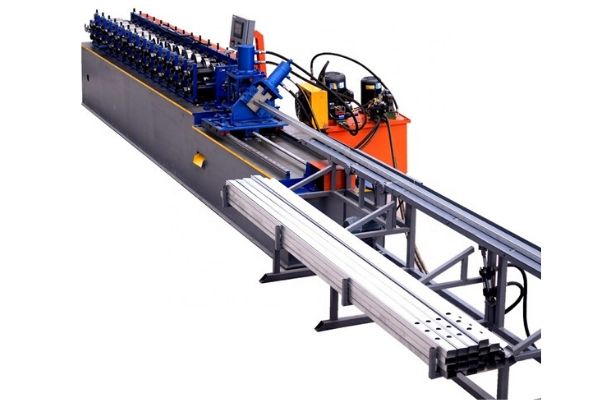

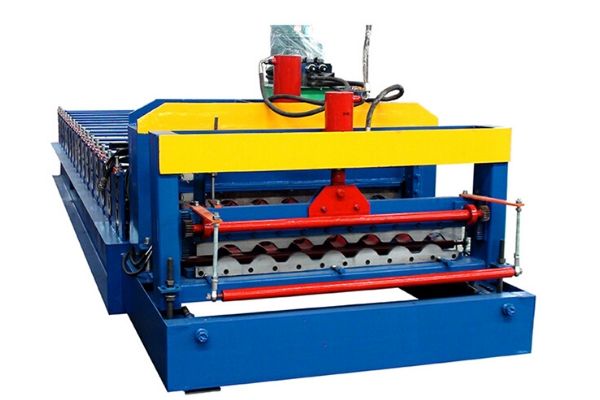

C channel roll forming machine is a single-coil forming unit that can produce various specifications of C-shaped products with a set of steel rolls. The C channel roll forming machine is mainly composed of a passive feeding rack, a feeding rack base, a feed introduction platform, a leveling device, a forming host, a punching device, a forming cutting device, a hydraulic station, and a computer control cabinet. This machine adopts automatic flying saw punching, which has the characteristics of easy operation and so on. The C channel is formed by rolling a thin steel plate.

The finished C channel produced by the C channel roll forming machine has good tension, bending and compression properties, and good flatness. The machine realizes full-automatic fixed-length cutting and automatic punching, which have the advantages of a high degree of automation, and quick and easy installation.

C channel roll forming machine greatly simplifies the production process, thus improving production efficiency. It can produce all kinds of profiles with different wall thickness and complex cross-section shapes and cold-formed steel with different materials that are difficult to produce by the general hot-rolling method. Cold-formed steel is the main material for making light-weight steel structures, made by cold bending of steel plates or steel strips.

The Advantages of C Channel Roll Forming Machine:

- Simple structure and beautiful appearance. Because the whole machine adopts a section steel structure, which is processed after welding, the structure is reasonable, the storage capacity is strong, and the operation is stable and reliable.

- Other important parts and components of the machine are all adopting parts of well-known domestic enterprises, thus effectively guaranteeing the performance of the equipment.

- The machine adopts full-automatic fixed-length cutting. The length of the product is accurate, the shape of the head and tail is beautiful and neat, without deformation.

- The machine is easy to install and debug, simple, and easy to operate, which is suitable not only for factory production but also can be transported to the construction site for processing.

- The machine has low noise, no pollution, and low consumption.

Common Troubles That May Appear During Operation:

- C channel small-side slant: Adjusting the nip roller at the feed end. If the small side at the left side is large, the left-end nip roller should be loosened and the right-end nip roller should be tightened (Note: Adjustment properly).

- Horizontal bending of C Channel: If the C channel is bent to the left, loosen the second row of left-end nip rollers at the discharge end and tighten the right-end nip rollers (Note: Adjustment properly).

- Longitudinal bending: When the C channel bends upward, press down the last row of straightening shafts. When bending downwards, press the second row of straightening shafts (Note: Adjustment properly).

C Channel Roll Forming Machine Operation and Matters Needing Attention:

When installing the mold, the power must be turned off. Manually move the electric idea belt or large gear to index the table and raise the slide to a high point. It is best to use an object to support between the table and the bottom surface of the slide to prevent the slide from falling and causing an accident. Before using the equipment, check whether the connections are firm and the bolts and nuts are tight.

Sufficient lubricating oil should be added to the left and right chassis to power on the starter for a test drive. Carefully observe the operation of the empty car first, whether there is noise, whether the oil is coming from the oil window, and whether the movement of each part of the C channel roll forming machine is coordinated. Only then can the mold be installed.

FAQ:

The main features of the C-Z Channel Roll Forming Machine are as follows:

- Cutting without changing the tool.

- Quick change. Any type change within three minutes.

- Adjustability. Webs, flanges, and flange edges can be made and adjusted in millimeters.

- C-Z type channel integrated roll forming machine. C-Z type change in three-step.

- Coaxial design. Reduced the problem of unequal height on both sides due to broken shaft.

The Specification of C Channel Roll Forming Machine:

Product: C Channel Roll Forming Machine

Work Pressure: 195 Mpa—350 Mpa

Voltage: 380V/50HZ 3Phase

Dimension(L*W*H): 3000*800*1400mm

Control System: PLC with touch screen

Roll material: 45# high-grade steel

Frame material: 300 H-high grade steel

Cutting type: Hydraulic cutting

Production Capacity: 8~12m/min

Power(W): 15KW+5.5KW

Weight: 5.6 T

Working material: Cold Roll Steel(CRC)

Shaft Diameter: 42 Mm

Thickness: 1.5-3.5mm

Application Industries: Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Restaurant, Retail, Food Shop, Printing Shops, Construction works, Energy & Mining, Food & Beverage Shops

Price: $18,000.00-$19,000.00