Dx51d z140 refers to steel products with high formability for cold forming, as indicated in the first letter D. The letter X indicates no specific substrate. The numbers 5 and 1 show the steel grade bearing its serial number, while the second D represents the hot-dip galvanizing code.

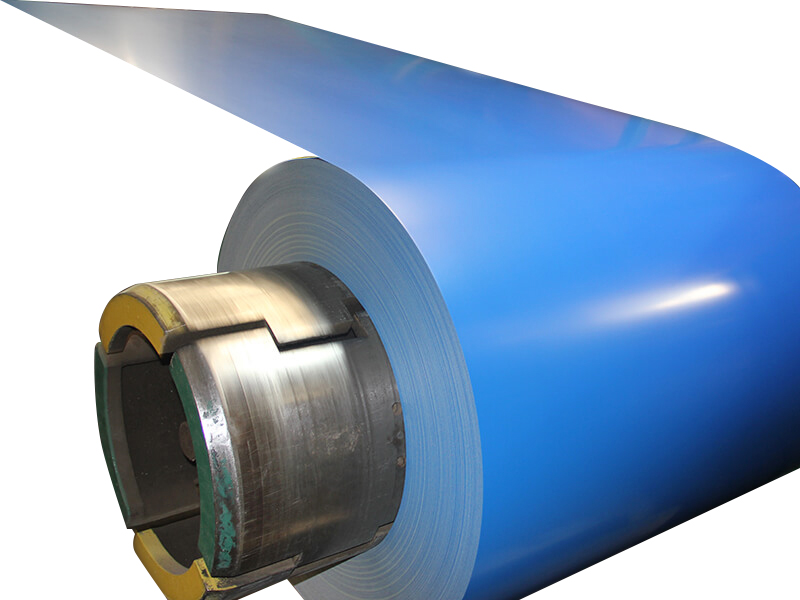

This galvanized steel coil has a high coating of pure zinc (Z) with a base material of low carbon. It underwent several stages of chemical process to protect it from abrasion and corrosion even after years of use. The zinc coating prevents rust from attacking the surface and inner parts. The steel undergoes a hot bath of molten zinc to become a permanent part of it and not work as a sealer or paint.

The addition of z140 refers to the zinc coating mass, which has a greater mass for weldability, formability, and bending applications.

What does z140 mean?

Z140 is a coating designation of the galvanized steel coils. Its minimum total coating mass for both surfaces have a symbol of g/m2 or grams per square meter. Under this designation, the steel got a triple spot test of 140 and a single spot test of 120 g/m2.

The guidance value for coating thickness per surface has a symbol μm, a ten (10) μm typical value with a range of 7 to 15. The surface quality of Z140 is X for the letter A under Normal spangle (N). The Minimized spangle (M) has a triple X under the letters A, B, and C.

The Normal spangle is the result of the zinc coating solidifying naturally to form zinc crystals or no spangle. The Minimized spangle is the product of influencing the solidification of the zinc coating to produce a few spangles, and some spangles are not visible.