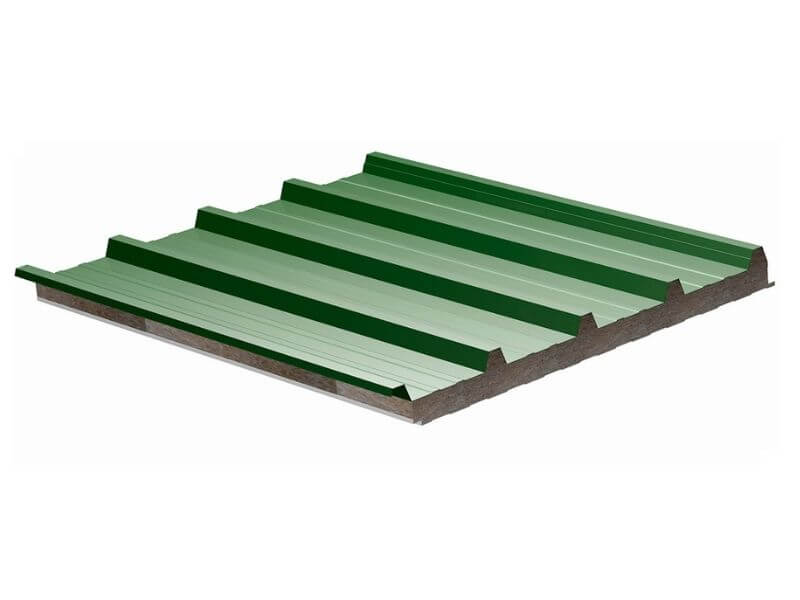

Rock Wool Sandwich Panel

RockWool Sandwich Panel Specification

| Product | Rock Wool Sandwich Panel |

|---|---|

| Thickness | 50mm 75mm 100mm 150mm 200mm |

| Mental Thickness | 0.3~0.6mm |

| Width | 950mm 960mm 1150mm |

| Density | 120~150kg/m3 |

| Application | Steel Structure Building/Shed/Steel Construction |

| Price | $10-19/ Meter |

| HS Code | 73809000 |

Advantages of Rock Wool Sandwich Panel:

- Excellent fire-resistance performance: The raw materials, production process, and formula used in the rock wool sandwich panel make it have good fire performance. Tests show that it has a fire resistance of more than 1000 ° C.

- Good thermal insulation.

- Significant sound absorption and heat insulation effect:

- Sound insulation: The rockwool sandwich panel has a significant reduction effect on noise transmission, and is especially suitable for places where designated flights pass by. In addition, after using the rockwool roof panel, the impact of rain and hail on the roof steel plate of the building caused the indoor sound, which was also significantly reduced.

- Sound absorption: The rock wool sandwich panel also has an excellent attraction effect, it can absorb sound in a relatively wide frequency range.

Characteristics of RockWool Sandwich Panel:

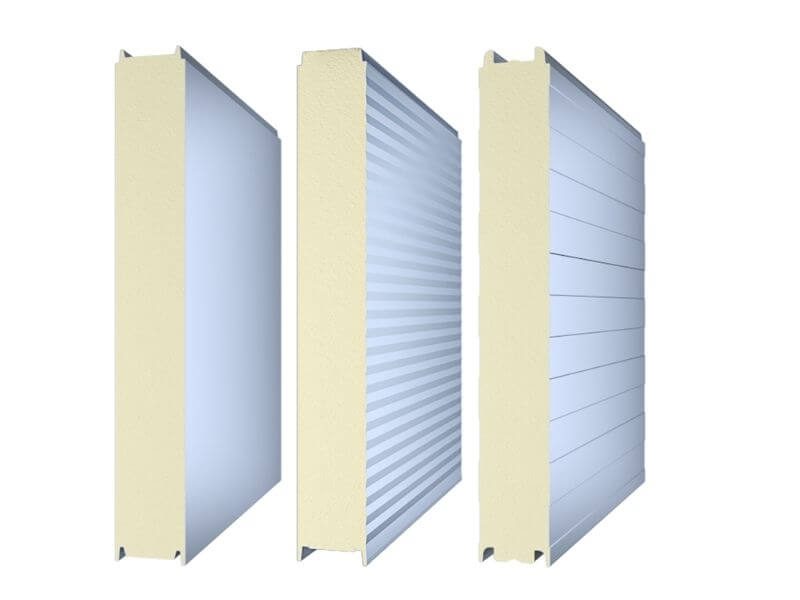

- Sealing performance: Polyurethane double-sided sealing rock wool sandwich panel adopts the production line process, thus taking advantage of the excellent waterproofness of polyurethane products to overcome the shortcomings of rock wool easy to absorb water deliquescence, and effectively extend the service life of the product in terms of physical properties.

- Beautiful performance: The interface is designed according to European standards. The appearance is round and smooth, the surface is smooth and beautiful, the joints are tight, the strength is reliable, and the generation of cold and hot bridges is effectively prevented.

- Good rigidity: The polyurethane double-sided sealing rockwool core material is bonded to the two layers of steel plates to form a whole and work together, together with the corrugated pressure profile on the top surface of the roof panel, the overall stiffness is much better than that of the rockwool (glass fiber) Cotton) on-site composite sheet. After the sandwich panel is fixed to the purlin by the connecting piece, the overall rigidity of the roof is greatly improved, and the overall working performance of the roof is strengthened. The rock wool sandwich panel is selected, and a larger purlin distance can be used, so the amount of purlin can be saved by 1/3 ~ 2/3.

- The buckling method is reasonable: The two-sided polyurethane rockwool roof panels are connected by concealed buckles, which avoids the hidden leakage of the roof panel joints and saves the number of accessories.

- The fixing method is firm and reasonable: the polyurethane double-sided sealing rock wool roof panel is fixed with special M6 self-tapping screws and purlins, which can effectively resist external forces such as typhoons. Self-tapping screws are set at the peak position between the joints of the two panels of the roof panel, and a special waterproof structure is adopted to avoid weak points of waterproofing.

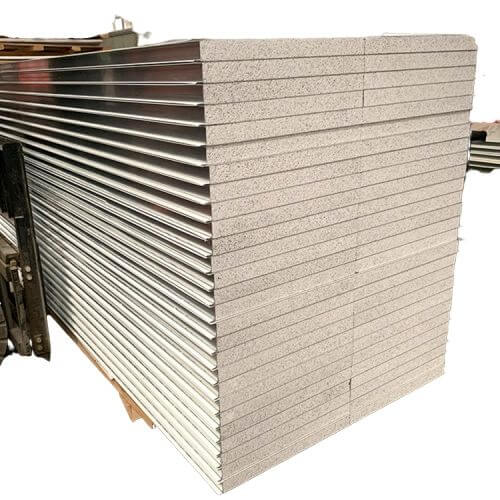

- Short installation cycle: Because there is no need for secondary processing on-site, the polyurethane double-sided sealing rock wool sandwich panel, not only can keep the surrounding environment tidy, does not affect the normal operation of other processes, but also can greatly shorten the installation cycle of the board. The daily installation area of rock wool sandwich panels is 600-800m2

- Anti-scratch protection: In the production of polyurethane double-sided sealing rock wool sandwich panel, polyethylene self-adhesive protective film can be pasted on the surface to avoid scratching or abrasion of the surface coating of the steel plate during transportation and installation.

Application of Rock Wool Sandwich Panel:

It is widely applied in the roof and wall of steel structure workshop, simple mobile house, and suspended ceiling and partition of air cleanroom.

FAQ:

How do you make RockWool Acoustic Panels?

A fireproof and soundproof rockwool thermal insulation board includes an upper rockwool board and a lower rock wool board and also includes a middle fireproof and soundproof layer. The middle fireproof and soundproof layer is obtained by splicing several soundproof plates, and the joint between two adjacent soundproof plates is filled with vitrified micro-beads.

Is rock wool mineralwool?

Mineral wool:

The molten metallurgical slag is made into a flocculent shape by spraying method or centrifugal method, which has the characteristics of heat insulation, sound absorption, corrosion resistance, non-combustibility, low price, and good waste.

Rock wool:

The natural rock such as dolomite, granite, and basalt rock is melted and then sprayed or centrifuged to make rock wool A. Its performance is the same as slag wool.

Rock Wool Insulated Roof Panels:

The rock wool board can be used as a roof. The general construction that uses rock wool board has excellent performance of fire prevention and heat insulation. Therefore, it is widely applied in various buildings. It is a kind of thermal insulation material with high-cost performance and excellent performance, which can meet the design requirements of building roofs.

Can Rock Wool cause cancer?

The history of rock wool in Japan was not very long, but it has been used for many decades in Europe, North America, and other regions, and has been widely used, but many people suspect that the fiber released by it will be inhaled during using, having the risk of suffering from cancer. To this end, the International Cancer Agency did a corresponding investigation and study. As a result, there was no evidence to prove that rock wool can increase the risk of lung cancer or mesothelioma. The following research also shows that it is the same for other cancers. Moreover, rock wool has been used as a thermal insulation material for a long time, and the decomposition rate is also very slow, which has deepened people’s misunderstanding. Many tests have been done, and it is found that most of them are non-carcinogenic. Only in extremely bad circumstances can cancers occur in experimental animals.