ASTM A653, or the standard specification for steel sheet, zinc-coated (galvanized) or zinc-iron alloy coated (galvannealed) by the Hot-Dip Process, shows products that conform to the latest applicable requirements of Specification A 924 (A924).

What is the G60 galvanized steel sheet in coil?

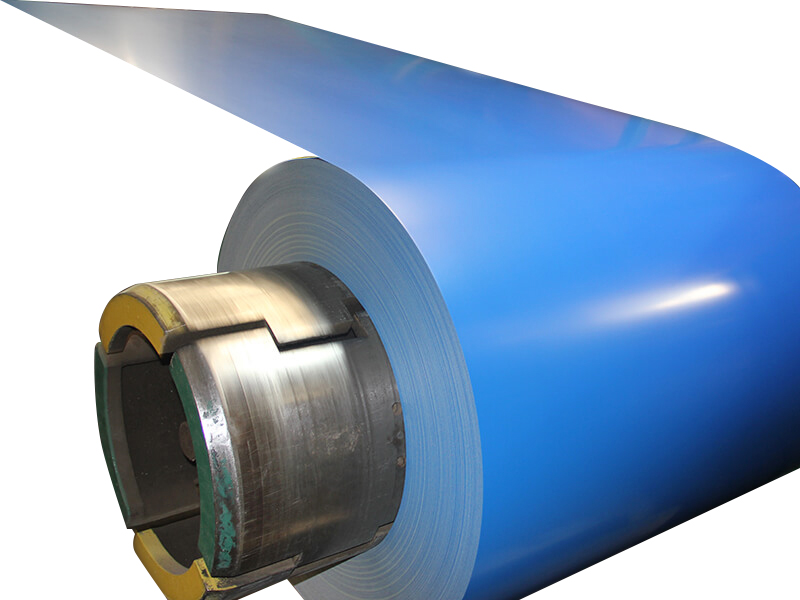

Galvanized steel sheet with G60 grade is coated with molten zinc. After being subjected to the continuous coating process that employs 600 feet per minute speed, the excess zinc on the steel sheet is removed by high-pressure air. This is to produce the required coating thickness. After it cools down, the sheet is rolled into coils to prepare it for fabrication.

G60 galvanized steel sheet in coil has a total coating weight of 0.60 oz/ft2 on both sides. The equivalent coating thickness on each side is 0.51 mils. Its coating is thinner compared to the items that went through the process of batch hot-dip galvanizing. While G60-grade galvanized steel sheet is not the best choice for the exterior environment, it offers long-term benefits when used in the interior and mild environments including appliances and ductworks.

What does G60 mean?

G60 is the coating grade for steel sheets that went through the continuous hot-dip coating process. G stands for “galvanized” or zinc-coating of the product. The number 60 refers to the zinc thickness surrounding the steel sheet or the total dual-sided coating. To get the amount of zinc coating on one side, you need to divide the number by two.

Other coating grades in ASTM A653 are G30, G90, G115, G140, G165, G185, G210, G235, G300, and G360.