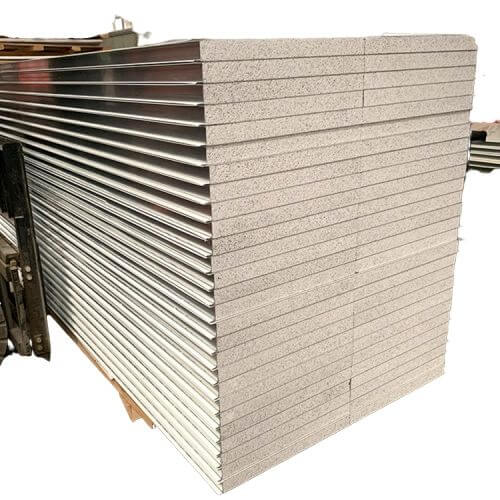

EPS Sandwich Panel

The Definition of the EPS Sandwich Panel:

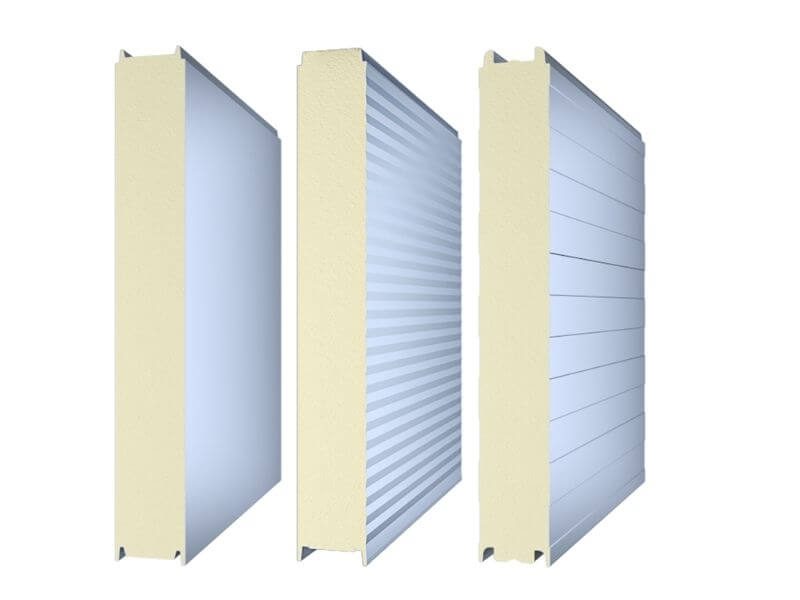

The inner and outer sides of the EPS sandwich panel are glass steel plates, and the sandwich layer is made of polystyrene foam. The surface of the sandwich panel is smooth and clean, and dirt can be easily removed. The entire panel is brightly colored and has excellent gloss retention. There is a layer of gel coat with excellent performance on the surface of the glass steel plate, which has good chemical stability to the atmosphere, water and general concentration of acids, alkalis, salts, and other media; the surface has high smoothness, excellent gloss retention, discoloration, corrosion resistance, and anti Light and anti-aging.

The Advantages of EPS Sandwich Panel:

- With the analysis of scientific testing data, the heat resistance of the EPS sandwich panel is equivalent to a brick wall being 75CM in thickness.

- The sound insulation effect and heat insulation effect of the EPS sandwich panel are more significant than others.

- Adopting steel structure as edge enhances the strength of the panel itself, and can independently support 5 meters in length.

- The fireproof grade of the EPS sandwich panel material can reach the B2 level.

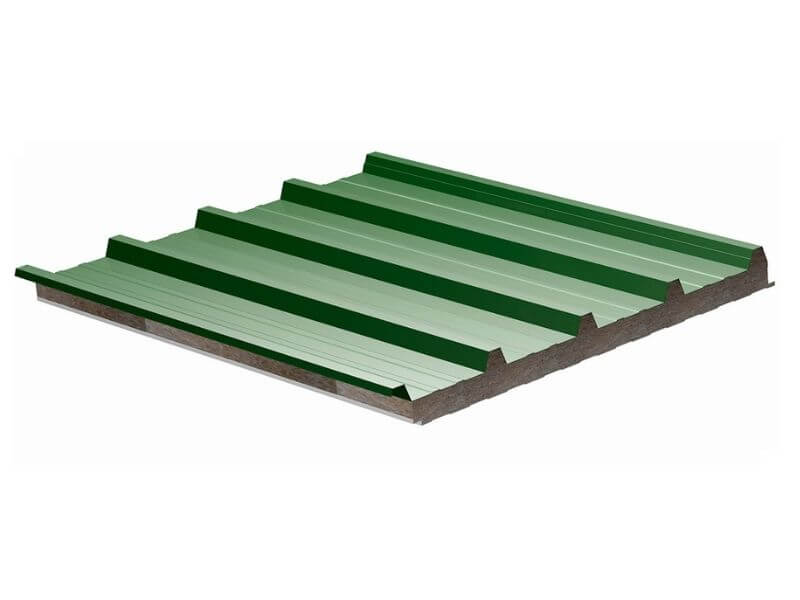

- It has a wide range of applications, such as roofing panels in construction projects and plant structures that require insulation. Specifically used in industrial plants, warehouses, exterior walls of the building materials and furniture market, roofs and partitions, meeting halls, building mezzanines, purification workshops, combined cold storage, mobile houses, toll stations, field operations, etc.

- It has the characteristics of thermal insulation, waterproof, fast construction, no need for decoration, lightweight and beautiful appearance.

The Specification of the EPS Sandwich Panel:

| Product | EPS Sandwich Panel |

|---|---|

| Steel Thickness | 0.3-0.6mm |

| Materials | EPS +Steel Sheet |

| Thickness | 60/75/90/100/120/150mm |

| Fireproof | >4 Hours |

| Sound Proof | 35-42dB |

| Moistureproof | <=10 |

| Length | Less Than 12meters |

| EPS Density | 5-25kgs/M3 |

| Application | External wall, Interior wall, floors, partition wall, roof, prefab house wall panel, fence and so on |

| Price | US $3.8-10/ Meter |

| HS Code | 73089000 |

The Application of the EPS Sandwich Panel:

It is applied in thermal insulation / dry truck compartments, large-span structural roofs, walls, thermal insulation (or fire protection) workshops, purification workshops, high- and mid-range combination houses, container houses, etc.

FAQ:

What is EPS?

Expanded Polystyrene (EPS) is a light-weight polymer. It is made of polystyrene resin, adding foaming agent, while heating to soften with gas generated, and finally form a rigid closed-cell foam.

What are the deferences between PU Sandwich Panel, Rock Wool Sandwich Panel, and EPS Sandwich Panel?

1. Different fire protection grades: Rock wool sandwich panel is class A, EPS sandwich panel is class B3, PU sandwich panel is class B1.

2. Different thermal insulation performance: PU sandwich panel is the best among the three.

3. Different waterproof performance: PU sandwich panel and EPS sandwich panel are superior to rock wool in the three.

4. Different density: the bulk density of rock wool sandwich panel is generally 120KG/m3, EPS sandwich panel is generally 16KG/m3, PU sandwich panel is generally 40KG/m3.

Is EPS Sandwich Panel flammable?

EPS polystyrene panel itself is a flammable material, so it is not a fireproof material in terms of fire rating. So it is not at all A level or B1 level. The fire resistance grades of the EPS panel on the market are only B2 (flammable) and B3 (flammable).

The difference between eps fire resistance class A, B, and B1:

1. Fire prevention coefficient: Class A is non-combustible; Class B is divided into three classes, B1, B2, and B3 have different degrees of combustion.

2. Flammability: Class A flammability is zero; B1 is flame retardant, B2 is flammable, and B3 is flammable.

What is a SIP panel construction?

SIP construction is a kind of prefabricated house with a SIP panel and installed on site. SIP panel generally uses OSB as the panel and polyurethane PU as the core material; glass magnesium panel, cement fiberboard, and other materials can also be used as the panel, EPS, rock wool and other materials are thermal insulation materials. All pipelines in the SIP house are set in the wall or floor, which can effectively increase the use area and make the utilization rate as high as 85%~90%.

How thick is a SIP panel?

The thickness of the SIP panel can range from 4 inches to 12 inches (approximately from 10.16 cm to 30.48 cm).