G90 galvanized steel sheet is a coating thickness designation specified under ASTM A653 galvanizing specification. It indicates a zinc coating of 0.90 ounces per square foot (oz/ft2).

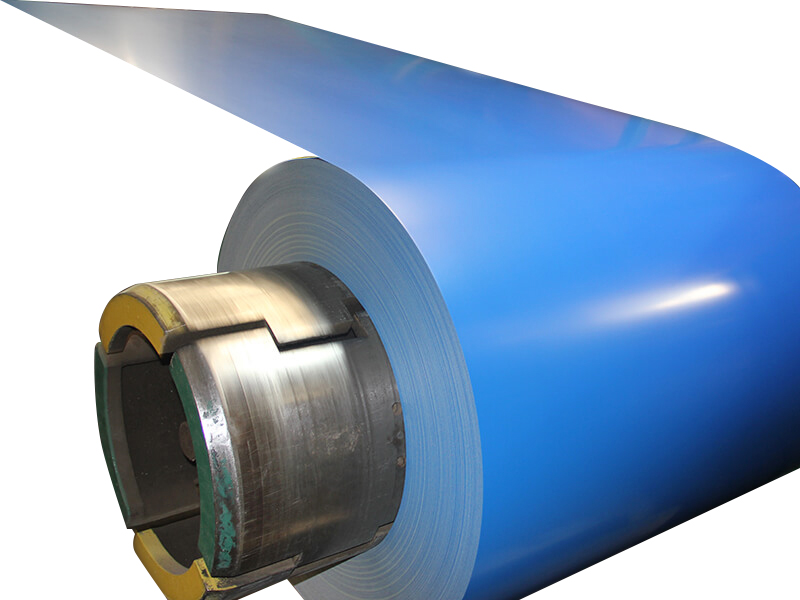

What is G90 galvanized steel coil?

G90 galvanized steel coils are cold-rolled steel sheets hot-dipped in zinc coating for increased durability. Specifically, these galvanized steel coils should have a triple-spot test (TST) average minimum zinc coating weight of 0.90 ounces per square foot on both sides or a minimum of 0.32 ounces per square foot on each side.

Meanwhile, if it’s under a single-spot test (SST), the steel must have an average minimum coating weight of 0.80 ounces per square foot on both sides.

The standard rule for protective coating is that the heavier the coating, the higher its durability. Hence, G90 galvanized steel coil has the most extended service life compared to other coating designations, G60, G40, and G30. Products under the G90 specification are primarily used in high moisture environments because they have higher resistance to corrosive environments.

What does G90 mean?

G90 refers to the coating type and the weight of the coating layer applied to the steel coil or sheet.

‘G’ means the coating is galvanized, which means zinc-coated. Meanwhile, the number ‘90’ stands for the weight of the zinc applied to the steel. Manufacturers measure the coating weight using the unit ounces per square foot (oz/ft2).

The coating designation G90 simply means that the two-sided zinc-coating on the steel weighs 0.90 ounces per square foot.