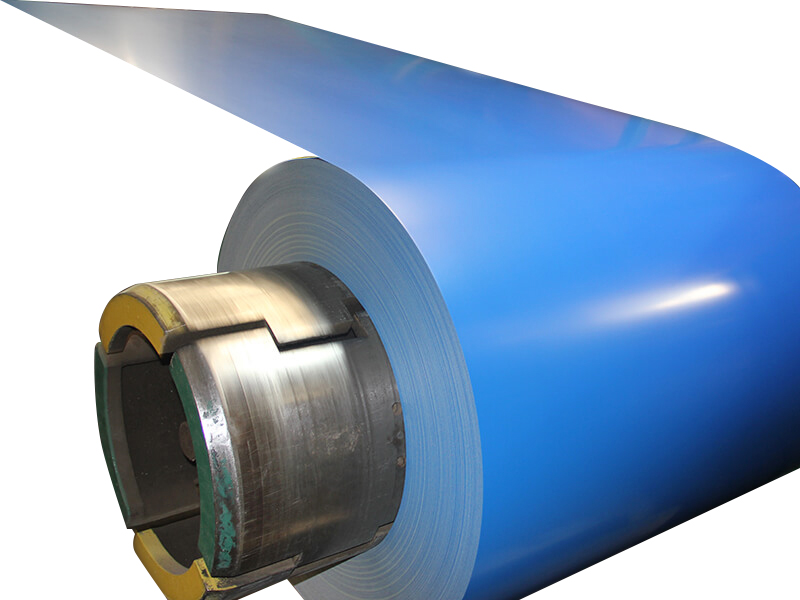

Dx51d AZ150 is a hot-dip aluminum-zinc steel alloy with a coating of 55 percent aluminum, 1.6 percent silicon, and 43.4 percent zinc. The chemical composition of Dx51d AZ150 offers superior resistance to heat and corrosion, with high thermal reflectivity and conductivity.

DX51D has a steel number 1.0917 with a chemical composition of 1,20 Manganese, 0,12 Phosporous, and 0,18 Carbon. Manufacturers immerse the prepared steel strip in a molten bath containing aluminum, zinc, and silicon. The molten bath’s composition is 1.6 percent silicon and 55 percent aluminum, and the balance goes to zinc.

Steel with DX51D brand has high elasticity and flexibility that adheres to the BS EN 10346:2015 standard for continuously hot-dip coated low– carbon products.

The continuous hot-dip coated steel has a nominal gauge of 0.57 to 2.00mm, minimum yield strength of 270 to 500MPa, and minimum elongation ratio of 22 percent.

Advantage

DX51D AZ150 aluminum-zinc steel alloy has excellent bending and proofing quality due to its high aluminum and zinc contents. The steel is resistant to high temperatures of over 300 degrees C, which works similarly to the aluminum-plated steel plate with its high-temperature resistance of more than 300 degrees C.

The steel is flexible and malleable, making it easy to manipulate in making an oven, chimney tube, fluorescent lamp shade, and illuminator.

The steel has a smooth and flat finish with high formability, which makes it easy to shear, stamp, and weld into various forms. It has superior surface conductivity and corrosion resistance when exposed to a harsh environment compared to galvanized steel sheets with the same thickness.

Uses

DX51D AZ150 aluminum-zinc steel has multiple uses in various industries. It is an excellent material for roofing and walling in the building and construction industries. Its benefits include corrugated boards, flue pipes, gutters, painting basis sheets, and agricultural equipment for barns and granaries.

The auto industry uses Aluzinc DX51D AZ150 for cold forming due to its superior cold-forming aptitude and corrosion protection. Its hard surface makes it a popular material for car parts as it can withstand abrasion. Its flexibility makes it a suitable material for welding due to its higher zinc coating.