The manufacture of steel coil is essential in almost all types of industries, buildings, and infrastructure constructions. The process begins by placing a sheet or a slab of steel into a rolling machine until the thickness has reduced. The finished product becomes resilient, corrosion-resistant, and high-performing steel sheets that are rolled into coils.

What is Steel Coil

The steel coil is a product of rolling and winding a piece of steel strip or steel sheet. The width of a steel coil is larger compared to its thickness. The method of producing steel coil is based on how it should be classified, whether as a cold-rolled, galvanized, or hot-rolled steel coil.

Steel manufacturers employ a process by which a steel sheet or strip is placed into a rolling machine. The purpose of this is to attain stronger, sturdier, ductile, and high-grade steel products that work according to international standards, such as JIS, American or European standards.

Steel Coil Classification

Hot-Rolled Steel Coil

Hot-rolled steel coil refers to steel that undergoes rolling in a mill process at a temperature that is above the recrystallization point, which is higher than 1000 degrees Fahrenheit. At this highest temperature point, the steel reaches malleability, which allows it to shape and form easily.

This method gives way to the production of multiple steel quantities. Once the steel has become malleable, it is allowed to cool at room temperature to reduce the stress it generated during work hardening.

As the steel has cooled down, it shrinks unevenly, which offers less control of the entire shape and size of the hot-rolled steel coil.

Steel grade:

Commercial Steel Types A, B, and C

Drawing Steel Types A and B

Structural Steel (SS Grades 30, 33, & 36), Types 1 & 2, 40, 45, 50, and 55

High-Strength Low-Alloy Steel (HSLAS) Classes 1 & 2, Grades 45- 65, and 70

HSLAS-F-Grades 50, 60, 70, and 80

Hot Rolled Pickled and Oiled Steel Coil

Hot rolled pickled and oiled steel refers to steel that undergoes descaling of its oxide film using hydrochloric acid bath. It will then be oiled to prevent rust formation, removes stains and contaminants, and improves formability.

The process of pickling and oiling a steel sheet offers cleaner surface that is easy to apply paint, deter corrosion and prevent degradation. The process of descaling occurs at ambient temperature and atmospheric pressure.

Pickling and oiling methods are effective in making the steel sheet or slab malleable, sturdier, cleaner surface, and resilient against wear and tear. The finished product becomes easier to use in structural applications.

Steel grade:

A36, A1011, A1018 (High Strength)

CQ (Commercial Quality)

Structural Grades 30, 33, 36, & 40, 36T2, 45 to 80, and 45T2

HSLA -Grades 45C1, 45C2, 50C1, 70C1, 70C2

Common Grades-CSA, CSB, CSC, BH, FSA, FSB, DDS, & EDDS

Cold-Rolled Steel Coil

Cold rolled steel coil refers to steel that is pressed between two rollers at room temperature. A weak acid solution is applied on hot rolled steel during the pickling process that begins with cleaning, brushing, drying, and oiling.

Once the surface has been applied with a thin film of oil, it will then undergo uncoiling and finally cold rolling. A size-reduction machine is used to wind up the steel into coils. A cold-rolled steel coil is stronger than hot-rolled steel by 20 percent due to strain hardening.

The shape is formed after several stages of breaking down, such as semi-finishing, sizing, semi-roughing, roughing, and finishing.

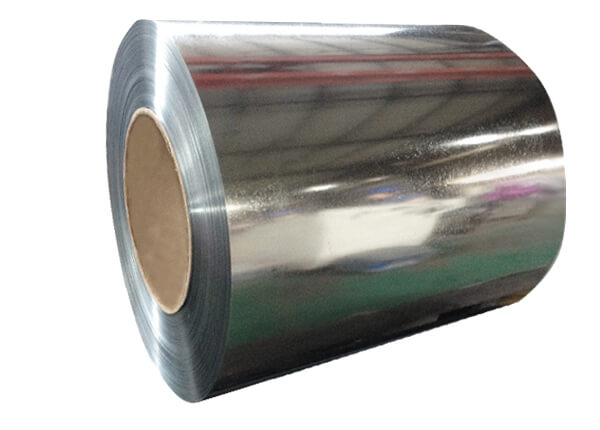

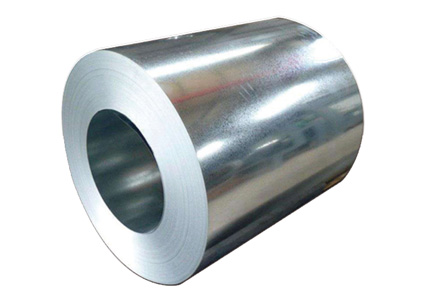

Galvanized Steel Coil

Galvanized steel coil refers to rolled coil steel product that has been cleaned and heated before it is dipped into molten zinc. The hot-rolled or cold-rolled steel strip, sheet, or slab can be coated with zinc and iron (GA) or zinc (GI).

The process of making galvanized steel coil uses an electrolytic deposition or a hot dipping process. The hot-dip method helps the steel from developing rust formation as both sides are coated with a layer of zinc.

The zinc-alloy bonding layer formation uses a diffusion process when the molten zinc is still in contact with the heated steel.

Steel grade:

Commercial Steel Types A, B, & C

Forming Steel Types A & B

Deep Drawing Steel Types A & C

Extra Deep Drawing Steel

Structural Steel

HSLAS

HSLAS-F

Solution Hardened Steel

Bake Hardenable Steel

Galvalume & Aluzinc Steel Coil

Galvalume & Aluzinc steel coil refers to steel coil that is produced by solidifying the substrate into 55 percent aluminum, 43.4 percent zinc, and 1.6 percent silicon at 600 degrees C. The end product goes by different names, such as Aluzinc, Zincalume, or Galvalume.

The raw material in producing the Galvalume & Aluzinc steel coil is a cold-rolled steel sheet, which serves as a substrate during the solidification of the silicon, aluminum and zinc.

The purpose of this is to provide durability, extra-strength and impervious properties of aluminum. The zinc offers electrochemical and galvanic protection to the steel coil.

Available in various grades as specified by the ASTM DIN GB JIS3302 standards

Pre-painted Steel Coil

The pre-painted steel coil is a steel product that has a film coating on its surface that act as a corrosion-resistant substrate. The coating process on the steel strip or sheet is done on a continuous process known as coil coating that yields a uniform paint finish.

The steel is unwound and cleansed well before applying chemicals on either or both surfaces. The surface can be applied with coating and primer or oven cured and rewound depending on the product specifications and applications.

The surface coatings help protect from exposure to the elements and prevent wear and tear for years.

FAQ

How to measure the thickness of a steel coil?

Measuring the thickness of the steel coil is made from the exposed side using ultrasonic thickness measurements. This is the easiest way to calculate the thickness of the entire width of the steel coil. The thickness may vary from 0.05 to 0.10mm or 0.002mm to 0.004mm from the center to the edges.

How to calculate the weight of a steel coil?

The formula for calculating a steel coil weight is L = (Weight)*1000/(D*W*T). The approximate weight is calculated by measuring the width, outside diameter (OD), and inside diameter (ID).

1000 stands as a coefficient to determine the dimensions of the Length in (m) and the Volume in (dm^3). The weight of the coil ranges from 7-15 tons.

Conclusion

Did you find it easy to understand the process of making steel coil? Steel coils have various methods of producing them depending on their applications and uses. Each coil type has its own specifications and availability. Overall, steel coils have multiple uses in various industries from automobile, home appliances, industrial and building constructions, many more.