ZAM steel is a cost-effective brand due to its high resistance to corrosion from its alloy of zinc, aluminum, and magnesium. Let’s learn more about ZAM steel.

What is ZAM steel?

ZAM steel is a brand of steel made by Nippon Steel Corporation. This hot-dip coated steel sheet boasts of its ability to fight corrosion over many years of use. The coating layer consists of 6 percent aluminum, 3 percent magnesium, and the rest is zinc. ZAM is an acronym for zinc, aluminum, and magnesium.

ZAM steel has a wide market due to its unique composition and long-lasting performance compared to hot-dip galvanized coatings. The technological advancement of ZAM makes it a sought-after brand worldwide that complies with the AS1397:2011 standards.

The blend of aluminum and magnesium makes the steel resistant to corrosion and scratches. The aluminum content is the secret to its high formability, which makes ZAM versatile in various applications.

ZAM’s superior anti-corrosion properties make it an excellent material for structures that are exposed to harsh environments. Its applications include boat and marina sheds, horticultural and agricultural sheds, refineries, spa and pool areas, and outdoor composite slabs.

Corrosion resistance mechanism of ZAM steel

ZAM’s corrosion resistance mechanism is due to its coating layer of aluminum and magnesium. The blend of Mg and Al creates an enduring protective film on its zinc base, giving protection against corrosion.

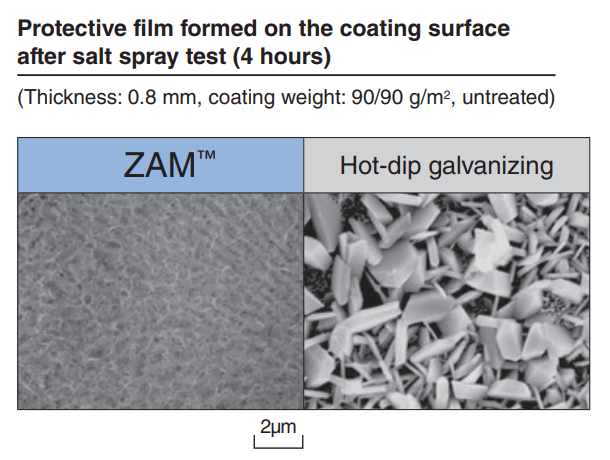

Compared to hot-dip galvanized coating layers, ZAM offers a finer and tighter adhesive property on the substrate. ZAM’s coating surfaces block the corrosive action over a long period of exposure to harsh environments.

In a salt spray test that lasted for four hours on both ZAM and hot-dip galvanized steel, ZAM formed a protective film on the coating surface. Take a glimpse at the figure below:

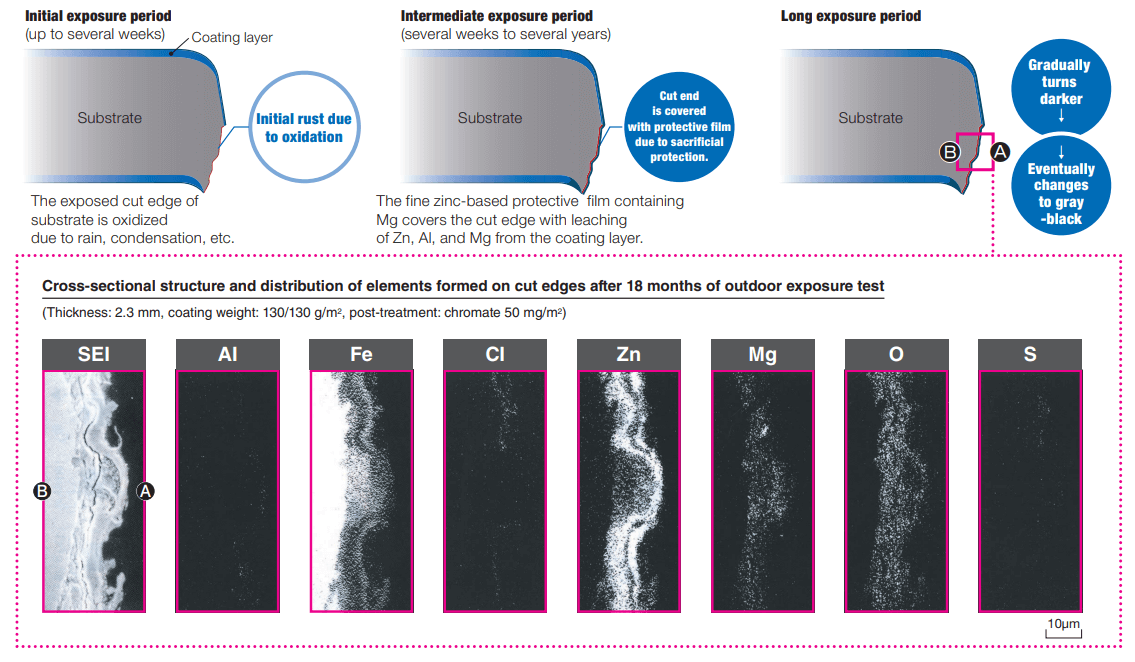

The cut-edge parts of the ZAM steel have superior corrosion resistance. The ends are covered with a fine base that contains a protective film comprising aluminum and magnesium leaching on its coating layer.

The corrosion resistance on the cut edge was based on a test on the steel substrate. The initial exposure period took several weeks, during which there was an initial rust on the exposed cut edge. The rust formed due to oxidation from condensation and rain.

The intermediate exposure period took several weeks to years. During this period, the cut edge resists corrosion due to the fine zinc-based protective film, which has a leaching of zinc, aluminum, and magnesium coating layers. The substrate turns darker to gray-black over the years of exposure to the elements.

Weldability

The coating layer of ZAM steel affects its weldability performance due to its zinc base. Zinc has a low melting point, which is not ideal for arc welding. This application leads to weak joints and deformation compared to cold- and hot-rolled steel sheets.

ZAM is prone to splashing, hole formation, and cracking. ZAM performs better if you weld it into joints, provided the structure has adequate strength and is under proper conditions.

Experts recommend conducting tests when welding ZAM steel to achieve greater strength and maximum welding parameters. The weld quality depends on the type of welding machine and shape of the joints.

Defective joints are avoidable if you follow the right conditions when welding ZAM steel. The joints should have enough weld strength and adequate internal sectional structure before welding the steel.

Applications

ZAM is a versatile steel brand that is useful in various applications. ZAM is popular choice in the building and construction sector. It is used for making refrigerant ducts, ceiling crosspieces, indoor baseball fields, sound barrier louvers, heavy-duty shutters, and house frames.

In road and civil engineering, its uses include bridge reinforcing plate, soundproof wall (ZPG treatment), wind barrier panel, sound barrier, sound barrier member, snow fence, guardrail, bridge railing, pipe for joining bolts of concrete block, rock bolt, windbreak screen, drain reinforcement pipe, handrail in tunnel, steel pipe pile, and fireproof protection for optical fiber.

ZAM is ideal for making automobile parts such as wiper linkage, filter case, radiator fan motor cover, starter motor yoke, hood lock, horn, pulley, splash guard, window regulator motor yoke, tank heat protector, constant velocity joint cover, and lower sash.

ZAM steel is also used in making electric power and electric equipment, farming structures, railroads, housing, and construction.

Conclusion

ZAM steel is a high-performing brand that can withstand corrosion even after many years of use. The color may fade, but its resistance to corrosion is unmatched compared to galvanized sheets.

References:

https://www.nipponsteel.com/product/catalog_download/pdf/U110en.pdf

ZAM Case Study. Nipponsteel