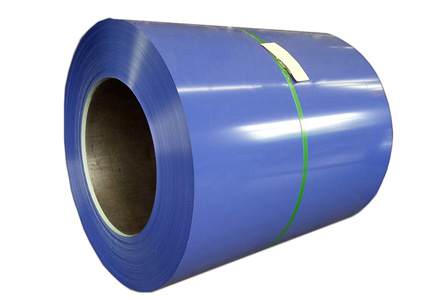

ASTM A755 refers to the Standard Specification for Steel Sheet, Metallic Coated by the Hot-Dip Process and Prepainted by the Coil-Coating Process for Exterior Exposed Building Products.

This standard is issued under the fixed designation A755/A755M; the number immediately following the designation indicates the yearof original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers steel sheet metallic coated by the hot-dip process and coil-coated with organic films forexterior exposed building products. Sheet of this designation is furnished in coils, cut lengths, and formed cut lengths. Building products include corrugated and various types of roll and brake-formed configurations.

1.2 The substrate is available in several different metallic-coated steel sheet products as enumerated in 4.1, depending on the requirements of the purchaser.

1.3 Coating systems supplied under this specification consist of a primer coat covered by various types and thicknesses of top coats. The combination of primer and top coat is classed as either a two-coat thin-film system or as a two-coat (or more) thick-film system. Typical top-coating materials are: polyester, silicone polyester, acrylic, fluoropolymer, plastisol, or polyurethane.

1.4 This specification is applicable to orders in either inch-pound units (as A755) or SI units [as A755M]. Values in inch-pound units and SI units are not necessarily equivalent. Within the text, SI units are shown in brackets. Each system shall be used independently of each other.

1.5 Unless the order specifies the “M” designation (SI units) the product shall be furnished to inch-pound units.

1.6 The text of this specification references notes and footnotes that provide explanatory material. These notes and footnotes, excluding those in tables and figures, shall not be considered as requirements of this specification.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards

A463/A463M Specification for Steel Sheet, Aluminum Coated, by the Hot-Dip Process

A653/A653M Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process

A792/A792M Specification for Steel Sheet, 55 % Aluminum-Zinc Alloy-Coated by the Hot-Dip Process

A875/A875M Specification for Steel Sheet, Zinc-5 % Aluminum Alloy-Coated by the Hot-Dip Process

A902 Terminology Relating to Metallic Coated Steel Products

A924/A924M Specification for General Requirements for Steel Sheet, Metallic-Coated by the Hot-Dip Process

A1046/A1046M Specification for Steel Sheet, Zinc Aluminum-MagnesiumAlloy-Coated by the Hot-Dip Process

A1063/A1063M Specification for Steel Sheet, Twin-Roll Cast, Zinc-Coated (Galvanized) by the Hot-Dip Process

B117 Practice for Operating Salt Spray (Fog) Apparatus

D522 Test Methods for Mandrel Bend Test of Attached Organic Coatings

D523 Test Method for Specular Gloss

D659 Method for Evaluating Degree of Chalking of Exterior Paints (Withdrawn 1990) 3

D714 Test Method for Evaluating Degree of Blistering of Paints

D822 Practice for Filtered Open-Flame Carbon-Arc Exposures of Paint and Related Coatings

D870 Practice for Testing Water Resistance of Coatings Using Water Immersion

D1005 Test Method for Measurement of Dry-Film Thickness of Organic Coatings Using Micrometers

D1654 Test Method for Evaluation of Painted or Coated Specimens Subjected to Corrosive Environments

D1735 Practice for Testing Water Resistance of Coatings Using Water Fog Apparatus

D2240 Test Method for Rubber Property—Durometer Hardness

D2244 Practice for Calculation of Color Tolerances and Color Differences from Instrumentally Measured Color Coordinates

D2247 Practice for Testing Water Resistance of Coatings in 100 % Relative Humidity

D2370 Test Method for Tensile Properties of Organic Coatings

D3359 Test Methods for Measuring Adhesion by Tape Test

D3363 Test Method for Film Hardness by Pencil Test

D4145 Test Method for Coating Flexibility of Prepainted Sheet

D4214 Test Methods for Evaluating the Degree of Chalking of Exterior Paint Films

G85 Practice for Modified Salt Spray (Fog) Testing

3. Terminology

3.1 Definitions:

3.1.1 Substrate—For definitions of terms relating to the substrate, see Terminology A902.

3.1.2 Coatings:

3.1.2.1 acrylic, n—a polymer based on resins prepared from a combination of acrylic and methacrylic esters, acrylic and methacrylic acids, and styrene; they contain one or more functional groups such as amide, hydroxy, or carboxy and form thermosetting systems on baking by cross-linking with themselves, or amino or epoxy resins.

3.1.2.2 conversion coating, n—a chemical treatment, normally applied to a metal surface prior to final finishing, which is designed to react with and modify the metal to produce a surface suitable for painting.

3.1.2.3 epoxy, n—polymers based on epoxy resins, which are the reaction product of epichlorohydrin and biphenol-Aand are cross-linked with amino or urea-formaldehyde resins to form thermosetting systems on baking.

3.1.2.4 fluorocarbon, n—polymers based on fluorocarbon resins made by the polymerization of vinyl fluoride monomer (PVF) or vinylidene fluoride monomer (PVF2); these resins are formulated into coatings by dispersion of finely divided particles in dispersants and diluents and form thermosetting systems on baking.

3.1.2.5 plastisol, n—a dispersion of finely divided vinyl resin in plasticizers; during the baking process, the resin particles are solvated by the plasticizer and fuse into a continuous film.

3.1.2.6 polyester, n—a polymer based on the condensation products of polybasic acids and diols (dihydric alcohols), also called oil-alkyds; they are modified by the addition reaction of monomers such as styrene or acrylic esters; polyester resins are cross-linked with amino resins to form thermosetting systems on baking.

3.1.2.7 polyurethane, n—a polymer produced by the addition reaction of an acrylic polyol or polyester polyol with an isocyanate-containing compound to produce thermosetting systems on baking.

3.1.2.8 primer, n—the first complete layer of paint of a coating system applied to an uncoated surface; the type of primer varies with the type of surface and its condition, the intended purpose, and the coating system being used.

3.1.2.9 silicone polyester, n—a polymer which is the reac- tion product between an organo-siloxane intermediate and an alkyd resin, or a cold blend of a silicone resin and a compatible

alkyd resin; these resins are cross-linked with amino resins to form thermosetting systems on baking.

3.1.3 Coating Characteristics:

3.1.3.1 chalking, v—the formation on a pigmented coating of a friable powder evolved from the film itself at or just beneath the surface.

3.1.3.2 fade, v—a loss in color intensity experienced by pigmented organic coatings over time, generally due to the effect of ultraviolet radiation.

3.1.3.3 gloss, n—the luster, shininess, or reflecting ability of a surface.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 bottom side, n—the side of prepainted sheet opposite the exposed weathering side.

3.2.2 coil coating, v—a continuous process by which paint and other coatings are applied and baked onto a moving strip of steel sheet.

3.2.2.1 Discussion—Rolls are used to pick up, meter, and deposit the liquid coating onto the moving strip and are also used to support the strip through the line. The product of this process is called prepainted steel sheet.

3.2.3 mil, n—a unit of length equal to 0.001 in. [25.4 µm], used for describing the thickness of paint coatings.

3.2.4 paint, n— of coil coating, an organic liquid, pigmented/nonpigmented, which is converted to a solid film by baking.

3.2.5 roll former, n—an apparatus that forms a continuous strip of metal into various shapes by a series of contoured steel rolls.

3.2.6 top side, n—the side of the prepainted sheet which is exposed to weathering.

3.2.7 washcoat, n—a thin organic coating, usually a polyester, applied to the back or unexposed side of prepainted sheet (also known as a backercoat).

3.2.7.1 Discussion—This pigmented/nonpigmented coating is applied for such reasons as protection of the topcoat while in coil form, interior appearance, and lubrication during roll forming.

4. Classification

4.1 The substrate shall conform to all requirements of the appropriate specification for the steel sheet product ordered as follows:

4.1.1 Zinc-Coated (Galvanized)—Specifications A653/ A653M and A1063/A1063M.

4.1.2 Zinc-5 % Aluminum Alloy-Coated—Specification A875/A875M.

4.1.3 55 % Aluminum-Zinc Alloy-Coated—Specification A792/A792M.

4.1.4 Aluminum Coated—Specification A463/A463M.

4.1.5 Zinc-Aluminum-Magnesium Alloy-Coated-Specification A1046/A1046M.

4.1.6 Each of the above-listed metallic-coated sheet specifications describes the range of available coating designations. The particular designation selected is related to the expected performance of the exterior exposed building product. Although there are exceptions based on the type of environment where the building is erected, the recommended minimum coating mass designations for use in exterior exposed building applications are:

| Metallic Coating | Minimum Recommended Coating |

|---|---|

| A653/A653M Zinc-Coated (Galvanized) | G90 [Z275] |

| A875/A875M Zinc-5 % Aluminum Alloy-Coated | GF75 [ZGF225] |

| A792/A792M 55 % Aluminum-Zinc Alloy-Coated | AZ50 [AZM150] |

| A463/A463M Aluminum Coated | T2 65 [T2 200] |

| A1046/A1046M Zinc-Aluminum-Magnesium Coated | ZM75 [ZMM220] |

| A1063/A1063M Zinc-Coated (Galvanized) | G90 [Z275] |

These minimum coating weight [mass] designations are important to attain the normally expected long-term product life in the application. Exceptions to these minimum designations can be considered when the environmental conditions are of low corrosive potential, such as a very dry climate. In these cases, a lower coating weight [mass], for example, G60 [Z180] may be appropriate. Similarly, for very corrosive environments, the user should consider specifying a coating designation with a heavier coating weight [mass].

4.2 The organic coating typically consists of a primer and a topcoat on the top (exposed) side and washcoat on the bottom (unexposed) side. Typical primers and topcoats are as follows:

4.2.1 Primers:

4.2.1.1 Epoxy.

4.2.1.2 Acrylic.

4.2.1.3 Polyurethane.

4.2.1.4 Polyester

4.2.2 Top Coats:

4.2.2.1 Polyester.

4.2.2.2 Silicone polyester.

4.2.2.3 Acrylic.

4.2.2.4 Fluoropolymer.

4.2.2.5 Plastisol.

4.2.2.6 Polyurethane.

4.2.3 Washcoats or Backercoats:

4.2.3.1 Polyester.

4.2.3.2 Acrylic.

4.3 Other coatings will be specified if agreed upon between the producer and the purchaser.

5. Ordering Information

5.1 The coated flat sheet covered by this specification is produced on continuous lines to decimal thickness only. The thickness of the sheet includes the base steel and the metallic coating. The thickness of the organic system is in addition to the substrate (base steel and metallic coating).

5.2 Orders for material under this specification shall include the following information, as applicable, to describe the required product adequately:

5.2.1 Product name (prepainted steel sheet),

5.2.2 ASTM designation and year of issue, as A755 – for inch-pound units or A755M – for SI units,

5.2.3 ASTM specification number of metallic coated substrate, steel sheet designation, and, if applicable, type (and grade, if required),

5.2.4 Metallic coating type (see 4.1),

5.2.5 Metallic coating weight [mass] designation,

5.2.6 Metallic coating finish (such as regular, minimized spangle, extra smooth, or minimized spangle-extra smooth).

5.2.7 Organic coating system designation (see 4.2 or 4.3),

5.2.8 Dry organic film thickness top side and bottom side (the top side will consist of a primer and topcoat and the bottom side will consist of a primer and a washcoat, or the same coating as the topside) (see 7.4.2),

5.2.9 Protection required (waxed or strippable coating),

5.2.10 Dimensions (thickness, width, either flat or formed (overall or cover) and length (if cut length)) and, if applicable, type of formed configuration,

5.2.11 Coil size requirement: maximum outside diameter, acceptable inside diameter, and maximum weight [mass],

5.2.12 Cut length requirement: maximum lift weight [mass],

5.2.13 Special requirements, if any, and

5.2.13.1 When the purchaser requires thickness tolerances for 3 / 8 -in. [10-mm] edge distance (see Supplementary Requirements section in Specification A924/A924M), this requirement shall be specified in the order of contract.

5.2.14 Application (part identification and description).

6. Substrate Requirements

6.1 For the purposes of this specification, substrate refers to the steel sheet and metallic coating. The specific requirements for the substrate are contained in the specifications listed in 4.1.

7. Organic Coating Requirements

7.1 The application of organic coatings on a continuous coil coating line, when producing products to the requirements of this specification, involves three major steps. These are: the application of a conversion coating, the application of a primer, and the application of one or more topcoats.

7.2 Conversion Coating—A conversion coating is a chemical treatment applied to the metal prior to application of the primer. It is designed to react with and modify the metal surface to enable chemical bonding to occur between the metal and the primer thus optimizing adhesion and corrosion resistance.

7.3 Primer:

7.3.1 The purpose of the primer is to serve as the bond between the substrate and the topcoat and to offer added corrosion protection for the entire system. For building products, primer thickness is typically 0.2 mil [0.005 mm] (tolerance 60.05 mil [0.001 mm]). Primers with films as thick as 3 mil [0.075 mm] (tolerance 60.30 mil [0.008 mm]) are available for end uses requiring high-performance.

7.3.2 Aprimer must be compatible with both the conversion coating and the topcoat in order to ensure optimum properties of the coating system. Care must be taken when choosing the primer to obtain the best possible performance for the service environment. For these reasons the primer is specified by the coating supplier or prepainted sheet producer.

7.3.3 See 4.2.1 for examples of typical primers.

7.4 Topcoat:

7.4.1 The topcoat provides color and durability and also acts as protection against atmospheric corrosion. Different topcoats are selected based on the performance or appearance requirements desired. For building products, topcoat thickness is nominally 0.8 mil [0.020 mm] (tolerance 60.2 mil [0.005 mm]). High performance topcoats with films as thick as 12 mil [0.30 mm] (tolerance 61.2 mil [0.03 mm]) are to be specified. Other upgraded systems will specify the application of two or more layers of topcoats.

7.4.2 The topcoat is applied to the top (exposed) side of the sheet and the wash coat or backercoat is applied to the bottom (unexposed) side of the sheet. Upon agreement between the producer and the purchaser, the bottom side will be coated the same as the top side.

7.4.3 See 4.2.2 for examples of typical topcoats.

7.4.4 The selection of a topcoat depends on the performance parameters required such as chalking and fading, plus the corrosion resistance needed, which must take into account the severity of the service environment.

7.5 Washcoat or Backercoat:

7.5.1 The washcoat or backercoat is applied to the bottom (unexposed) side of the sheet and is pigmented or not. Its purpose is to provide protection against damage to the top-side coating during shipment and storage and also to provide some additional durability to the unexposed side during the service life of the product. For building products, washcoat thickness is typically 0.3 mil [0.008 mm] (tolerance 60.05 mil [0.001 mm]).

7.5.2 See 4.2.3 for examples of typical washcoats.

7.6 Testing Requirements—The properties of the substrate and the organic coating system, combined with the method of forming, determine the life expectancy and general appearance of the final product. Each coating system has different qualities in regard to gloss, flexibility, fading, chalking, resistance to cracking at bends, abrasion resistance, dirt retention, and resistance to varying atmospheric conditions. All of these factors must be considered in any end application. The test methods used to measure some of these parameters are listed in Annex A1 and are normally considered to be mandatory requirements. The test methods listed in Appendix X1 are used to measure other parameters but are generally considered to be nonmandatory requirements. The specific requirements for each system must be agreed upon between the producer and the purchaser.

8. Packaging, Marking, and Loading

8.1 See Specification A924/A924M. In addition, coils will be shipped eye vertical to minimize transit abrasion. Rollformed panels require special packaging. Coil-coated steel is finished material and must be treated as such in handling and storage.

8.2 Proper on-site storage of building panels prior to erection has been found to be important in maintaining the integrity of the coating system. Corrosion failure will result when building panels are not properly protected from water being trapped during storage prior to installation. Pallets must be placed off the ground and at a slight angle for effective drainage. In addition, the use of metal covers or the equivalent is an effective way of keeping pallets dry. Do not use plastic bags to protect the coils or pallets.

9. Keywords

9.1 coatings, nonmetallic; coatings, painted; coil-coating process; painted sheet; roofing materials; siding materials; steel sheet