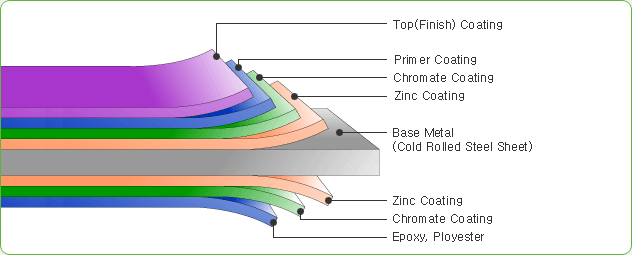

PPGL Coil Profile

This is the PPGL steel coil Profile:

- Top(Finish) Coating

- Primer Coating

- Chromate Coating

- Zinc Coating

- Base Metal(Cold Rolled Steel Sheet)

- Zinc Coating

- Chromate Coating

- Epoxy, Polyester

The substrate is an annealed cold-rolled steel coil.

Chromated paint is used for cleaning the surface of the cold-rolled coil.

After Chromated, the next is zinc coated. The coil becomes a galvalume steel coil now.

After zinc coated, the next is Chromated again, for cleaning the galvalume steel coil surface again.

The primer coating is used for increasing the adhesion of the top coating. When cold roll forms, the paint will not fall off.

The top paint coating metal is PE or PVDF.

PPGL Coil Price in Japan

The main factors affecting the price of PPGL are the price fluctuations of steel raw materials, the thickness, and width of the substrate, the type of coating, the thickness of the coating, and the weight of the zinc layer.

Recommended: