Advantages of hot–rolled steel coil :

1) Hot rolling can significantly reduce energy consumption and reduce costs. During hot rolling, the metal has high plasticity and low deformation resistance, which greatly reduces the energy consumption of metal deformation.

2) Hot rolling can improve the processing performance of metals and alloys. The coarse grains in the cast state will be broken, and the significant cracks will heal, reduce or eliminate the casting defects, transform the cast structure into a deformed structure, and improve the processing performance of the alloy.

3) Hot rolling usually adopts large ingots and large reduction rolling, which not only improves the production efficiency but also creates conditions for increasing the rolling speed, realizing the continuity and automation of the rolling process.

Mechanical Properties of Hot–rolled Steel coil

| Nominal thickness | Yield strength (Mpa) | Tensile strength (Mpa) | Elongation A50mm% | 180 degree bending test |

|---|---|---|---|---|

| >1.5-2.5 | ≤290 | ≥310 | ≥38 | D=0a |

| >2.5-3.0 | ≤290 | ≥300 | ≥38 | D=0a |

| >3.0-4.0 | ≤290 | ≥300 | ≥40 | D=1/2a |

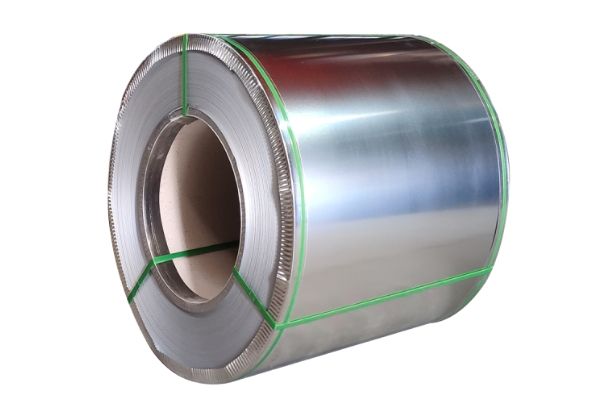

Specifications of Hot-rolled Steel coil

| Production | Hot-rolled steel coils |

|---|---|

| Technical | Hot rolled |

| Width | 1219-1500mm |

| Surface | coated or uncoated |

| Longth | Customer's Requirement |

| Thickness | 1.2-20mm |

| Weight | 5-28 tons |

| Price | US $520-640/ Ton |

| HS Code | 7208519000 |

| Application | Construction Steel Coil |

Common grades of hot-rolled steel coil:

- A36

- C1010

- C1018

- A1011

- C1026

- A500

- C1045

- C1141

Application of hot–rolled coil steel:

Hot-rolled coil products are widely used in cold-rolled substrates, ships, cars, bridges, construction, machinery, oil pipelines, pressure vessels, etc. due to their excellent strength, good durability, easy processing and outstanding weldability.

FAQ:

Will hot–rolled steel rust?

It will rust and is prone to rust.

Is hot or cold rolled steel stronger?

In terms of physical properties, cold-rolled steel is generally harder than hot-rolled steel. Since the metal is formed at a lower temperature, the hardness, tensile resistance and deformation resistance of the steel will increase according to work hardening.