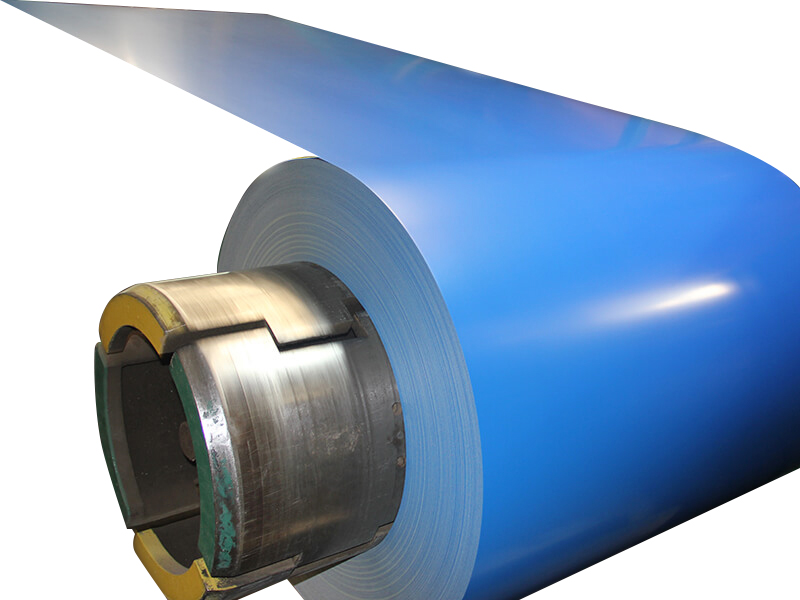

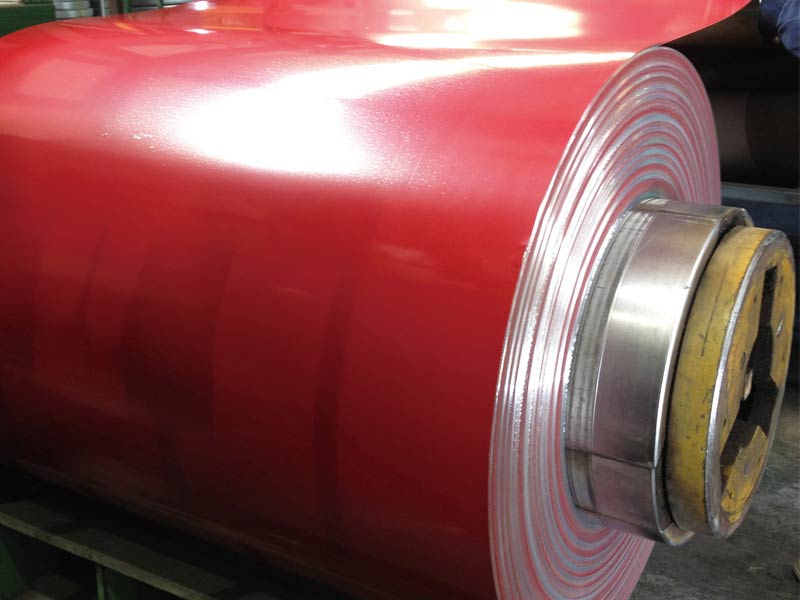

What is the use of Colour-coated steel?

Construction

Color-coated steel coils are mainly used in construction projects. After being processed into corrugated boards or sandwich panels, they are mainly used in industrial buildings such as industrial plants and warehouses. Civil buildings are mainly used in roofs, gutters, and siding.

Home appliances

Generally, electro-galvanized and cold plates are used as the substrate and are commonly used in refrigerator casings or large air conditioner casings, freezers, refrigerators, washing machine casings, etc.

5/5 - (7 votes)